Semicera iskeed u horumarisayQaybta Seal Seramic SiCwaxaa loogu talagalay in lagu buuxiyo heerarka sare ee wax soo saarka semiconductor casriga ah. Qaybtan xidhidhisku waxay isticmaashaa waxqabad sareSilicon carbide (SiC)walxo leh iska caabin aad u fiican iyo xasilooni kiimikaad si loo hubiyo waxqabadka xidhidhiyaha heer sare ah ee deegaan aad u daran. Lagu darayaluminium oxide (Al2O3)iyoSilicon nitride (Si3N4), Qaybtani waxay si fiican u qabataa codsiyada heerkulka sare waxayna si wax ku ool ah uga hortagi kartaa gaaska iyo dareeraha dareeraha.

Marka lala isticmaalo qalabka sidadoonyaha waferiyo sidayaal wafer, Semicera'sQaybta Seal Seramic SiCwaxay si weyn u wanaajin kartaa hufnaanta iyo isku halaynta nidaamka guud. Iska caabin heerkulkeedu sarreeyo iyo iska caabbinta daxalka ayaa ka dhigaysa qayb aan laga maarmi karin wax-soo-saarka semiconductor-ka saxda ah, hubinta xasilloonida iyo badbaadada inta lagu jiro habka wax-soo-saarka.

Intaa waxaa dheer, naqshadeynta qaybtan xiritaanka ayaa si taxadar leh loo hagaajiyay si loo hubiyo in ay ku habboon yihiin qalabyo kala duwan, taas oo fududeyneysa isticmaalka khadadka wax soo saarka ee kala duwan. Kooxda R&D ee Semicera waxay sii wadaan inay si adag uga shaqeeyaan sidii ay kor ugu qaadi lahaayeen hal-abuurnimada tignoolajiyada si loo hubiyo tartanka alaabteeda ee warshadaha.

Doorashada Semicera'sQaybta Seal Seramic SiC, waxaad heli doontaa isku-dhafka waxqabadka sare iyo isku-kalsoonaanta, kaa caawinaya inaad gaarto habab wax soo saar oo waxtar leh iyo tayada badeecada aad u fiican. Semicera had iyo jeer waxaa ka go'an in ay macaamiisha siiso xalalka semiconductor-ka ugu fiican iyo adeegyada si kor loogu qaado horumarka joogtada ah iyo horumarka warshadaha.

✓Tayada ugu sareysa ee suuqa Shiinaha

✓Adeeg wanaagsan mar walba adiga, 7*24 saacadood

✓Taariikhda gaaban ee dhalmada

✓ MOQ yar waa la soo dhawaynayaa waana la aqbalay

✓Adeegyada gaarka ah

Susceptor Kobaca Epitaxy

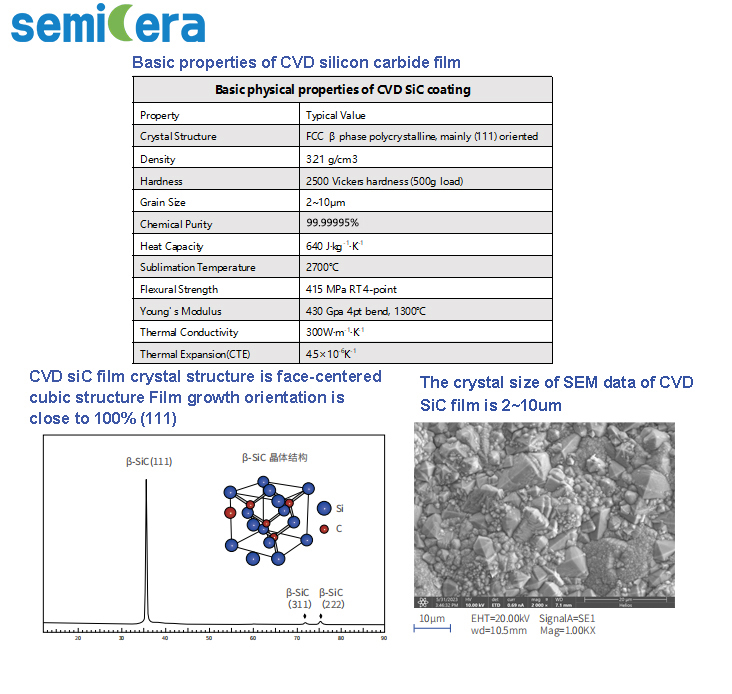

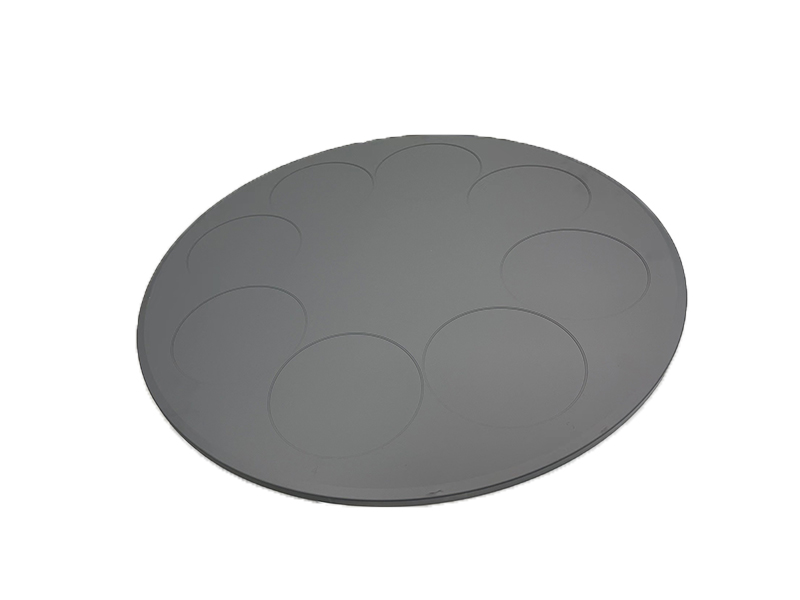

Silikoon/silicon carbide wafers waxay u baahan yihiin inay maraan habab badan si loogu isticmaalo aaladaha elektiroonigga ah. Habka muhiimka ah waa silikoon/sic epitaxy, kaas oo silikoon/sic wafers lagu qaado saldhigga garaafyada. Faa'iidooyinka gaarka ah ee saldhigga garaafiga ee silikoon carbide-dahaarka leh ee Semicera waxaa ka mid ah nadiifnimo aad u sareysa, daahan labbiska ah, iyo nolosha adeeg aad u dheer. Waxa kale oo ay leeyihiin iska caabin sare oo kiimikaad iyo xasilloonida kulaylka.

Soosaarka Chip LED

Inta lagu jiro dahaarka ballaaran ee reactor MOCVD, saldhigga meere ama qaade ayaa dhaqaajiya maraqa substrate-ka. Waxqabadka maaddada salka ayaa saameyn weyn ku leh tayada dahaarka, taas oo iyaduna saameynaysa heerka qashinka ee jajabka. Saldhigga dahaarka leh ee Silicon carbide ee Semicera wuxuu kordhiyaa waxtarka wax soo saarka ee waferrada LED-yada tayada sare leh wuxuuna yareeyaa weecasho dhererka hirarka. Waxaan sidoo kale siinaa qaybo garaafyo dheeri ah oo loogu talagalay dhammaan reactors MOCVD ee hadda la isticmaalo. Waxaan ku dabooli karnaa wax kasta oo leh daahan silikoon carbide ah, xitaa haddii dhexroorka ka kooban yahay ilaa 1.5M, waxaan weli ku dahaaran kartaa carbide silikon.

Goobta Semiconductor, Habka Faafinta Oxidationiwm.

Nidaamka semiconductor-ka, habka balaarinta oksaydhisku wuxuu u baahan yahay nadiifnimo sare leh, iyo Semicera waxaan ku siinnaa adeegyo daahan caado ah iyo CVD inta badan qaybaha silikoon carbide.

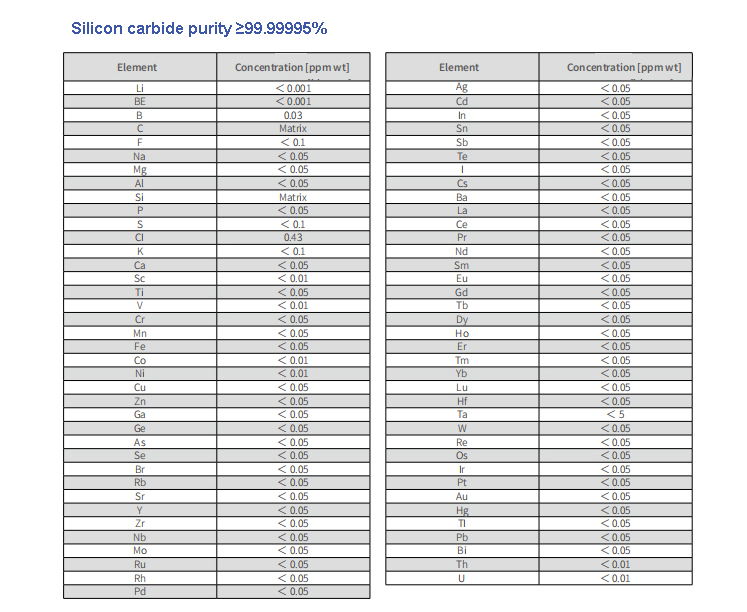

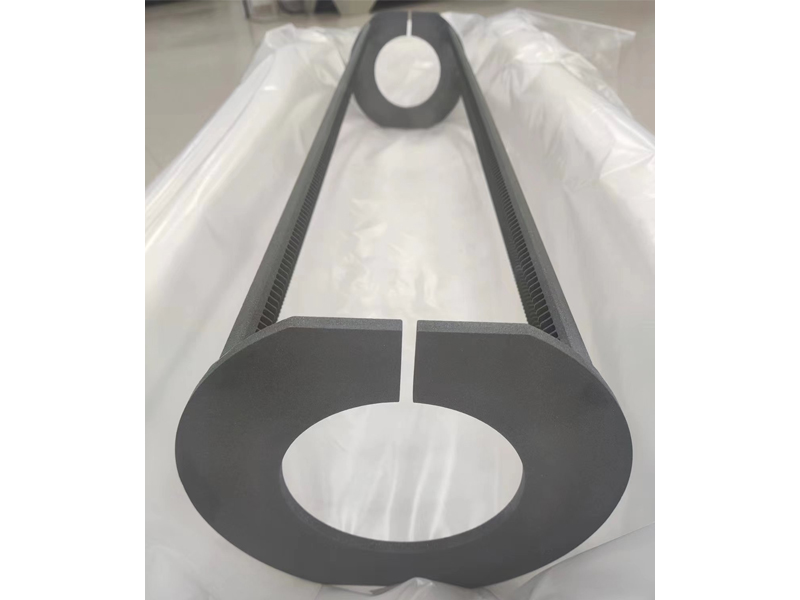

Sawirka soo socdaa wuxuu muujinayaa slurry silicon carbide slurry ee Semicea iyo tuubada foornada silikoon carbide ee lagu nadiifiyo 100ka0-heerboodh la'aanqolka. Shaqaalaheenu waxay shaqaynayaan ka hor dahaadhka. Nadiifinta carbide silikoonkeena waxay gaari kartaa 99.99%, daahirsanaanta daahan sic ayaa ka weyn 99.99995%.

Tuubada Silicon Carbide Paddle iyo Tube Process Tube Ceyriin oo Nadiifinaya

Silicon Carbide Wafer Doonta CVD SiC Dahaarka leh