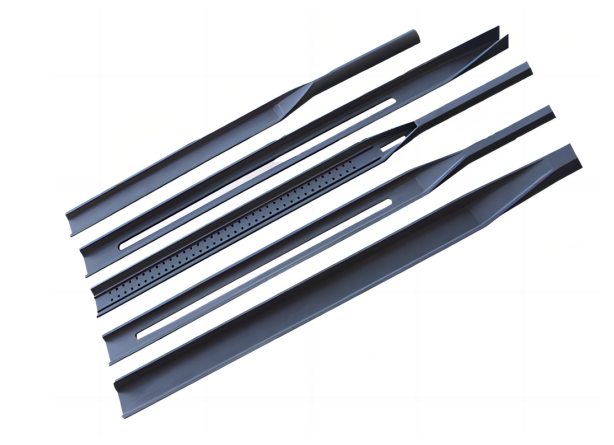

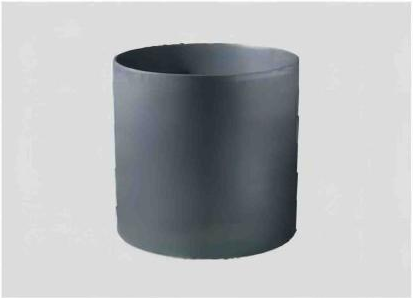

SiC Wafer Doon

Silicon carbide wafer doonwaa qalab xambaara oo loogu talagalay maraqyada, inta badan loo isticmaalo hababka faafinta qoraxda iyo semiconductor. Waxay leedahay astaamo ay ka mid yihiin iska caabbinta xirashada, iska caabinta daxalka, iska caabbinta heerkulka sare, iska caabinta bamka balasmaha, awoodda heerkulka sare ee heerkulka, kuleylka sare ee kuleylka, kuleylka sare ee kuleylka, iyo isticmaalka muddada-dheer ee aan sahlanayn qalloocinta iyo qalloocinta. Shirkaddayadu waxay isticmaashaa walxo silikoon carbide oo nadiif ah oo nadiif ah si loo hubiyo nolosha adeegga oo ay bixiso naqshado la habeeyey, oo ay ku jiraan. kala duwan oo toosan iyo toosandoon wafer.

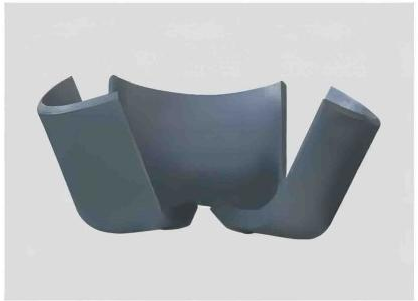

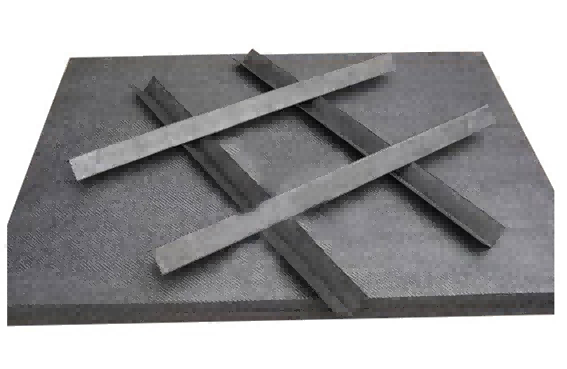

SiC Paddle

TheSilicon carbide cantilever paddleInta badan waxaa loo adeegsadaa dahaadhka (faafinta) ee waferrada silikoon, kaas oo door muhiim ah ka ciyaara rarida iyo qaadista waferrada silikoon heerkulka sare. Waa qayb muhiim ah oo ka mid ahwafer semiconductornidaamyada loading oo leh sifooyinka ugu muhiimsan ee soo socda:

1. Ma qalloocdo jawiga heerkulku sarreeyo waxayna leedahay cudud sare oo ku shubasho maraqa;

2. Waxay u adkaysataa qabow daran iyo kulayl degdeg ah, waxayna leedahay nolol adeeg oo dheer;

3. Isku-xidhka balaadhinta kulaylku waa mid yar, si weyn u kordhinaysa dayactirka iyo wareegga nadiifinta, waxayna si weyn u yareysaa wasakhowga.

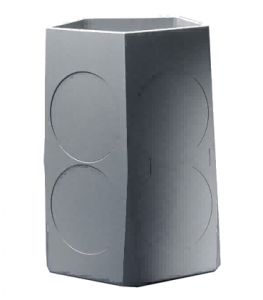

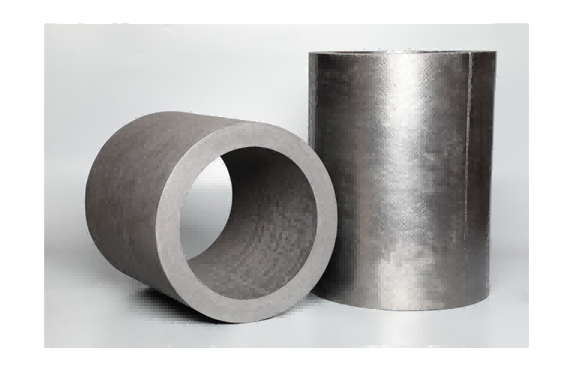

SiC Furnace Tube

Tuubbada habka carbide ee Silicon, oo ka samaysan SiC nadiif ah oo sare leh oo aan lahayn wasakh bir ah, ma wasakhayso waferka, waxayna ku habboon tahay hababka sida semiconductor iyo faafinta sawir-qaadista, annealing iyo habka oksaydhka.

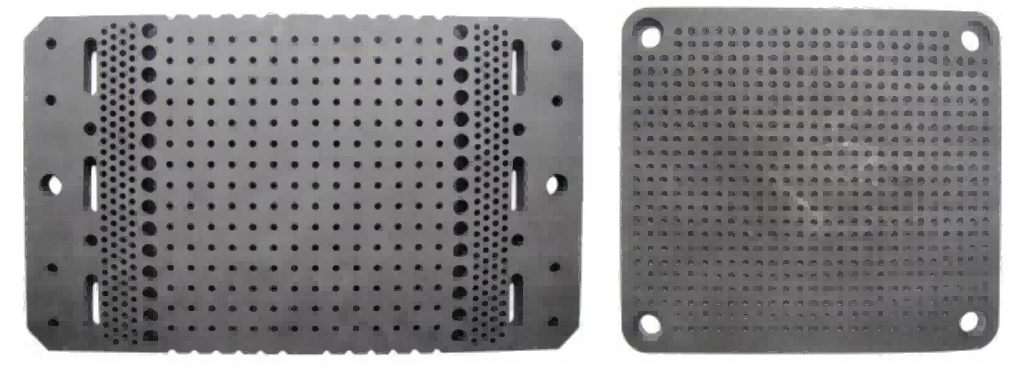

Gacanka Robot SiC

gacanta robot SiC, oo sidoo kale loo yaqaano dhamaadka wareejinta wareejinta wafer, waa cudud robotic ah oo loo isticmaalo in lagu qaado waferrada semiconductor waxaana si weyn loogu isticmaalaa warshadaha semiconductor, optoelectronic, iyo warshadaha tamarta qorraxda. Isticmaalka carbide silikoon nadiif ah oo nadiif ah, oo leh qallafsanaan sare, xidho iska caabin, iska caabin seismic, isticmaalka muddada-dheer ee aan qalloocin, nolosha adeegga dheer, iwm, waxay bixin kartaa adeegyo gaar ah.

Graphite ee koritaanka crystal

Gaashaanka kulaylka graphite

Tuubada korantada graphite

leexiyaha graphite

Garaafyada garaafka

Dhammaan hababka loo isticmaalo koritaannada semiconductor crvstals waxay ku shaqeeyaan heerkul sare iyo jawiyo wasakh ah. Aagga kulul ee foornada koritaanka kristanta waxaa badanaa lagu qurxiyaa kulaylka u adkaysta iyo nadiifinta sare ee daxalka. qaybaha graphite, sida kuleyliyaha graphite, crucibles, cylinders, deflector, chucks, tuubooyinka, giraanta, haystayaasha, lawska, iwm alaabta Our dhammeeyey gaari kartaa content ash ka yar 5ppm.

Garaafka loogu talagalay Semidonductor Epitax

MOCVD Qaybaha Garaafka

Qalabaynta Semiconductor Graphite

Habka Epitaxial waxaa loola jeedaa korriinka hal walxood oo kiristaalo ah oo ku yaal hal substrate crystal oo leh qaab isku mid ah oo lattice ah sida substrate-ka. Waxay u baahan tahay qaybo badan oo nadiif ah oo ultra-sare leh iyo saldhig garaafeed oo leh daahan SIC. Garaafyada nadiifka ah ee sare ee loo isticmaalo epitaxy semiconductor waxay leedahay codsiyo badan oo kala duwan, kuwaas oo la mid noqon kara qalabka inta badan loo isticmaalo warshadaha, Isla mar ahaantaana, waxay leedahay mid aad u sarreeya. daahirsanaan, dahaar lebbisan, nolol adeeg oo aad u wanaagsan, iyo iska caabin kiimiko oo aad u sarreeya iyo xasilloonida kulaylka.

Qalabka dahaarka iyo kuwa kale

Qalabka dahaarka kulaylka loo isticmaalo wax soo saarka semiconductor waa graphite adag dareemay, jilicsan, foil graphite, alaabta ka kooban carbon, iwm alaabta ceeriin waa alaabta graphite dibadda laga keeno, kaas oo la gooyn karaa si waafaqsan qeexidda macaamiisha, iyo sidoo kale waxaa loo iibin karaa sida oo dhan. Walxaha isku dhafan ee kaarboon waxaa inta badan loo adeegsadaa sida sideyaasha monocrystal qoraxda iyo habka wax soo saarka unugyada polysilicon.