-

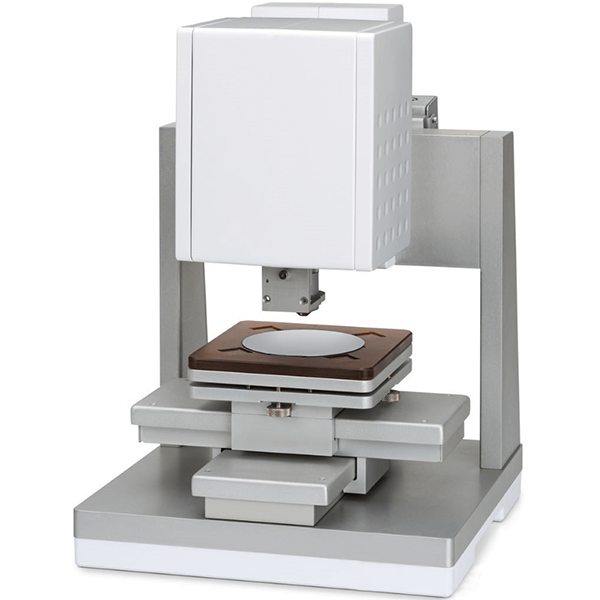

Waxqabadka Wacan ee Doomaha Wafer ee Silicon Carbide ee Kobaca Crystal

Nidaamyada korriinka kristal waxay ku jiraan wadnaha wax-soo-saarka semiconductor, halkaas oo wax soo saarka waferrada tayada sare leh ay muhiim u tahay. Qayb muhiim ah oo ka mid ah geeddi-socodkan waa doonida wafer ee silikoon carbide (SiC). Doomaha wafer-ka ee SiC ayaa aqoonsi weyn ka helay warshadaha marka laga reebo...Sii akhri -

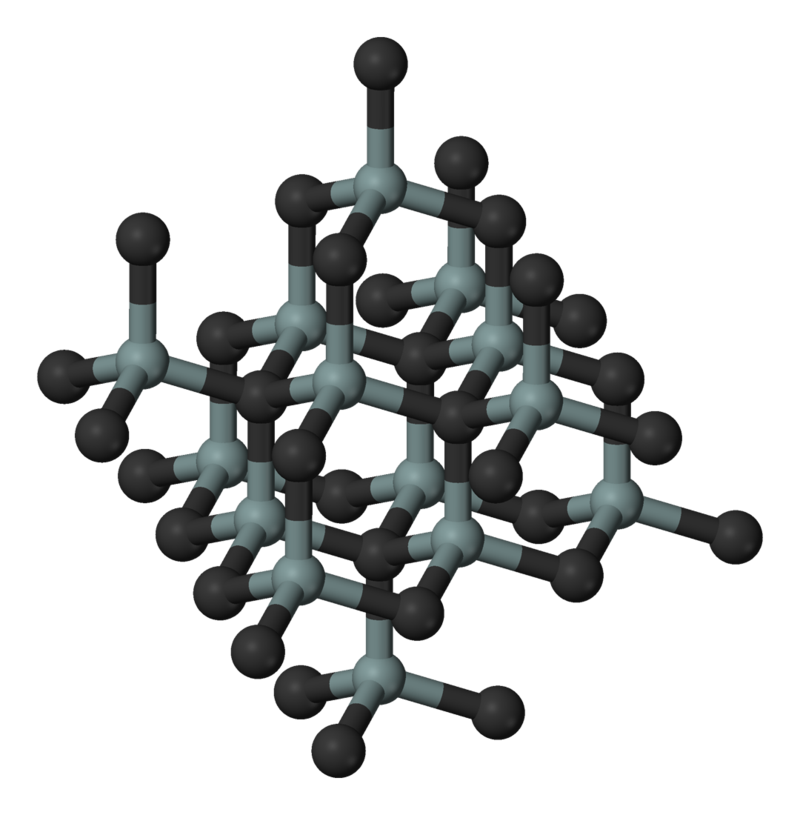

Habdhaqanka Kulaylka ee Cajiibka ah ee Kuleyliyeyaasha Graphite ee Goobaha Kulaylka Foornada Keliya ee Crystal

Marka la eego tignoolajiyada foornada crystal-ka ah, hufnaanta iyo saxda ah ee maaraynta kulaylka ayaa ugu muhiimsan. Helitaanka isku mid ahaanshaha heerkulka ugu wanaagsan iyo xasilloonida ayaa muhiim u ah koritaanka kiristaalo-kaliya tayada sare leh. Si wax looga qabto caqabadahan, kuleyliyeyaasha garaafyada ayaa u soo baxay sidii wax cajiib ah ...Sii akhri -

Xasiloonida kulaylka ee Qaybaha Quartz ee Warshadaha Semiconductor

Horudhac In industry semiconductor, xasiloonida kulaylku waa muhiimadda ugu weyn si loo hubiyo in la isku halayn karo oo hawlgelinta hufan ee qaybaha muhiimka ah. Quartz, oo ah qaab crystalline ah oo ah Silicon dioxide (SiO2), ayaa helay aqoonsi weyn oo ku saabsan sifooyinka xasilloonida kulaylka ee gaarka ah. T...Sii akhri -

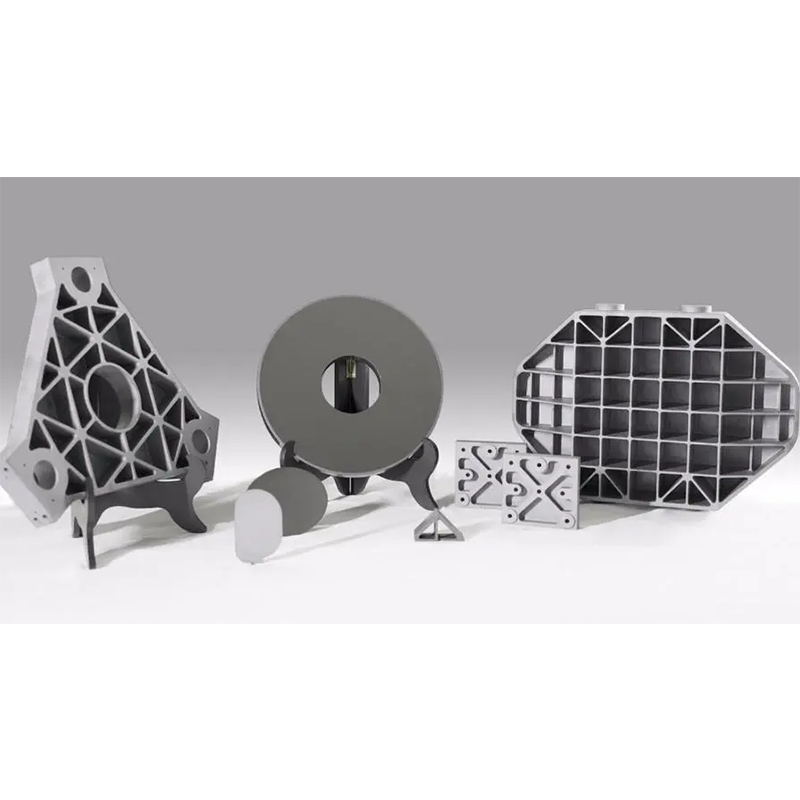

Iska caabinta Daxalka ee Tantalum Carbide Coatings ee Warshadaha Semiconductor

Ciwaanka: Iska caabinta Daxalka ee Tantalum Carbide Coatings ee Hordhaca Warshadaha Semiconductor In industry semiconductor, daxalka ayaa caqabad weyn ku ah cimriga dheer iyo waxqabadka qaybaha muhiimka ah. Dahaarka Tantalum carbide (TaC) ayaa u soo baxay sidii xal rajo leh ...Sii akhri -

Sidee loo cabbiraa caabbinta xaashida filim khafiif ah?

Filimada khafiifka ah ee loo isticmaalo wax soo saarka semiconductor dhamaantood waxay leeyihiin iska caabin, caabbinta filimku waxay saameyn toos ah ku leedahay waxqabadka aaladda. Caadi ahaan ma cabbirno caabbinta buuxda ee filimka, laakiin isticmaal caabbinta xaashida si aad u qeexdo. Waa maxay caabbinta xaashida iyo diidmada mugga...Sii akhri -

Codsiga CVD daahan carbide silicon si wax ku ool ah ma u hagaajin karaa nolosha shaqada ee qaybaha?

Daahan CVD silicon carbide waa tignoolajiyada samaysa filim khafiif ah oogada qaybaha, kaas oo ka dhigi kara qaybaha ay leeyihiin iska caabin fiican oo xidhashada, iska caabinta daxalka, iska caabinta heerkulka sare iyo guryaha kale. Guryahaan aadka u wanaagsan waxay ka dhigaan daahan CVD silicon carbide si ballaaranSii akhri -

Dahaarka CVD silikoon carbide ma leeyihiin sifooyin qoyaan aad u fiican?

Haa, dahaarka CVD silikoon carbide waxay leeyihiin sifooyin qoyaan aad u fiican. Qoyaanku waxa loola jeedaa awoodda shay si uu tamarta u daadiyo oo u yareeyo baaxadda gariirka marka uu la kulmo gariir ama saameyn. Codsiyo badan, guryaha qoynta ayaa aad looga soo dejiyaa...Sii akhri -

Silicon carbide semiconductor: deegaan ahaan saaxiibtinimo iyo mustaqbal hufan

Dhinaca agabka semiconductor-ka, Silicon carbide (SiC) waxa ay u soo baxday sidii musharrax rajo leh oo jiilka soo socda ee semiconductors hufan oo saaxiibtinimo leh. Iyada oo leh hantideeda gaarka ah iyo kartideeda, semiconductors silikoon carbide waxay u gogol xaareysaa si aad u waara...Sii akhri -

Rajada codsiga ee doomaha wafer silikoon carbide ee garoonka semiconductor

Goobta semiconductor, xulashada alaabtu waxay muhiim u tahay waxqabadka qalabka iyo horumarinta habka. Sanadihii la soo dhaafay, wafers carbide silicon, oo ah walxo soo baxaya, ayaa soo jiitay fiiro gaar ah waxayna muujiyeen karti weyn oo loogu talagalay codsiga goobta semiconductor. Silico...Sii akhri -

Rajada codsiga ee ceramics silikoon carbide berrinkii tamarta qorraxda ee photovoltaic

Sanadihii la soo dhaafay, sida baahida caalamiga ah ee tamarta dib loo cusboonaysiin karo ayaa kordhay, tamarta qorraxda ee photovoltaic waxay noqotay mid sii kordheysa oo muhiim ah sida ikhtiyaarka tamarta nadiifka ah. Horumarinta tignoolajiyada sawir-qaadista, sayniska maaddooyinka ayaa door muhiim ah ka ciyaara. Waxaa ka mid ah, ceramics silicon carbide, a ...Sii akhri -

Habka diyaarinta ee qaybaha garaafka dahaarka leh ee TaC ee caadiga ah

QAYBTA/1 CVD (Qaybta Uumiga Kiimikada): Markay tahay 900-2300℃, iyadoo la isticmaalayo TaCl5 iyo CnHm sida tantalum iyo ilo kaarboon, H₂ sida hoos u dhigista jawiga, Gaaska sidaha, filimka falcelinta falcelinta. Dahaarka la diyaariyey waa cufan, labis iyo nadiif sare. Si kastaba ha ahaatee, waxaa jira qaar ka mid ah pro ...Sii akhri -

Codsiga qaybaha garaafka dahaarka leh ee TaC

QAYBTA/1 Crucible, abuurka xajiyaha iyo giraanta hagaha ee SiC iyo AIN foornada quraaradda ah ayaa lagu koray habka PVT Sida ku cad sawirka 2 [1], marka habka gaadiidka uumiga jirka (PVT) loo isticmaalo diyaarinta SiC, crystal abuurka ayaa ku jira gobolka heerkulkiisu hooseeyo, SiC r...Sii akhri