Hordhaca CVD TaC Coating:

CVD TaC Coating waa tignoolajiyada adeegsata kaydka uumiga kiimikada si ay ugu shubto daahan tantalum carbide (TaC) dusha sare ee substrate-ka. Tantalum carbide waa walxo dhoobo ah oo tayo sare leh oo leh sifooyin farsamo iyo kiimiko oo aad u wanaagsan. Habka CVD wuxuu abuuraa filim TaC labis ah oogada sare ee substrate-ka iyada oo loo marayo falcelinta gaaska.

Tilmaamaha ugu muhiimsan:

Adag aad u fiican oo xidho iska caabinTantalum carbide waxay leedahay engegnaan aad u sarreeya, iyo CVD TaC Coating waxay si weyn u wanaajin kartaa caabbinta xirashada substrate-ka. Tani waxay ka dhigaysa dahaarka mid ku habboon codsiyada meelaha dharka sare leh, sida qalabka goynta iyo caaryada.

Deganaanshaha Heerkulka SareDahaarka TaC wuxuu ilaaliyaa foornada muhiimka ah iyo qaybaha reactor heerkul ah ilaa 2200 ° C, taasoo muujinaysa xasillooni wanaagsan. Waxay ilaalisaa xasiloonida kiimikaad iyo farsamada hoostooda xaaladaha heerkulka aadka u daran, taas oo ka dhigaysa mid ku habboon habaynta heerkulka sare iyo codsiyada jawi heerkul sare ah.

Degenaansho kiimikaad oo heer sare ah: Tantalum carbide waxay leedahay iska caabin adag oo daxalka ah inta badan asiidhyada iyo alkaliska, iyo CVD TaC Coating waxay si wax ku ool ah uga hortagi kartaa waxyeelada substrate-ka ee deegaanka daxalka.

Barta dhalaalka sare: Tantalum carbide waxay leedahay meel dhalaalkeedu sarreeyo (qiyaastii 3880 ° C), taas oo u oggolaanaysa CVD TaC Coating in loo isticmaalo xaaladaha heerkul aad u sarreeya iyada oo aan dhalaalilin ama hoos loo dhigin.

Dhaqdhaqaaq kuleyl oo heer sare ahDahaarka TaC wuxuu leeyahay kororka kuleylka sare, kaas oo gacan ka geysanaya inuu si wax ku ool ah u baabi'iyo kulaylka hababka heerkulka sare iyo ka hortagga kulaylka maxalliga ah.

Codsiyada suurtagalka ah:

• Gallium Nitride (GaN) iyo Silicon Carbide epitaxial CVD qaybaha reactor oo ay ku jiraan sida waferrada, suxuunta dayax-gacmeedka, madaxyada qubayska, saqafka, iyo kuwa wax u dhimaya.

• Silicon carbide, gallium nitride iyo aluminium nitride (AlN) qaybaha koritaanka crystal oo ay ku jiraan crucibles, xajiyeyaasha abuur, giraangiraha hagaha iyo filtarrada

• Qaybaha warshadaha oo ay ku jiraan walxaha kululaynta iska caabinta, tuubooyinka duritaannada, giraangiraha maaskarada iyo jigjiga birta

Astaamaha codsiga:

• Heerkulka oo deggan in ka sarreeya 2000°C, taas oo u oggolaanaysa in lagu shaqeeyo heerkul aad u daran

• U adkaysta hydrogen (Hz), ammonia (NH3), monosilane (SiH4) iyo silicon (Si), siinta ilaalinta deegaanka kiimikada adag

• Iska caabbinta shoogga kulaylka ayaa awood u siinaya wareegyo hawlgal oo degdeg ah

• Graphite waxay leedahay xabag adag, hubinta nolol adeeg dheer oo aan lahayn delamination dahaarka.

• Nadiifin aad u sarreeya si loo baabi'iyo wasakhda ama wasakhowga aan loo baahnayn

• Dabool dahaar ah oo waafaqsan dulqaadka cabbirka adag

Tilmaamaha farsamada:

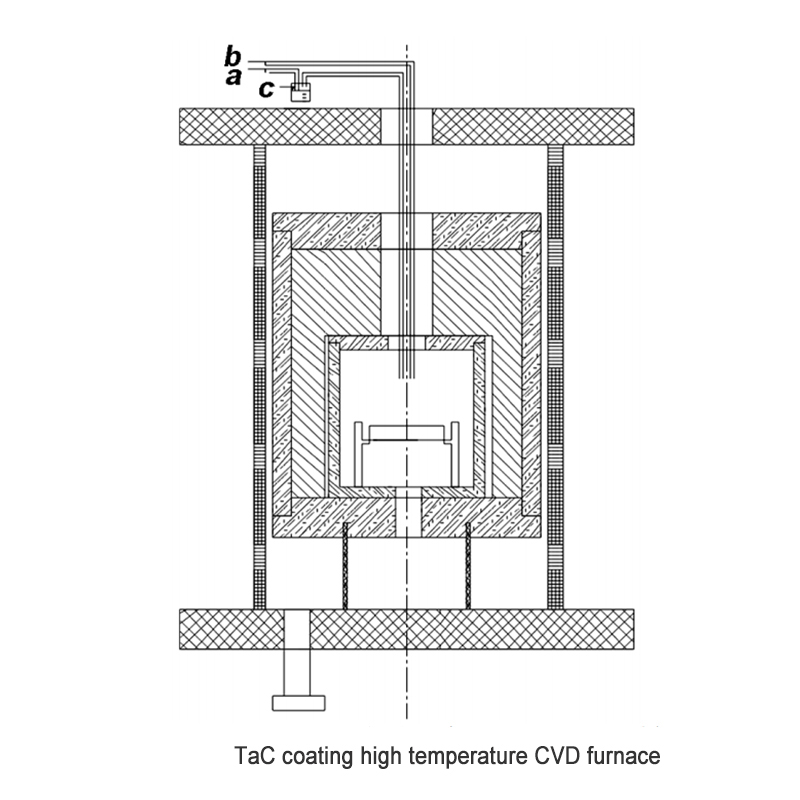

Diyaarinta dahaarka tantalum carbide cufan ee CVD:

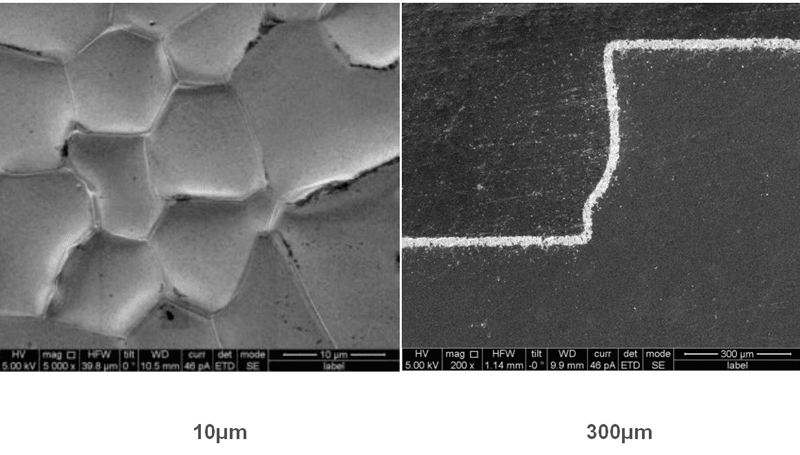

Daahan TAC oo leh crystallinity sare iyo lebis heer sare ah:

CVD TAC COATING Halbeegyada Farsamo_Semicera:

| Tilmaamaha jireed ee daahan TaC | |

| Cufnaanta | 14.3 (g/cm³) |

| Xoog-saarid badan | 8 x 1015/cm |

| Dheecaan gaar ah | 0.3 |

| Isku xidhka balaadhinta kulaylka | 6.3 10-6/K |

| Adag (HK) | 2000 HK |

| Iska caabin weyn | 4.5 ohm-cm |

| iska caabin | 1x10-5Ahm*cm |

| Deganaanshaha kulaylka | <2500℃ |

| Dhaqdhaqaaqa | 237 cm2/Vs |

| Cabbirka garaafiga ayaa isbeddela | -10 ~ -20um |

| Dhumucda dahaarka | ≥20um qiimaha caadiga ah (35um+10um) |

Kuwa kore waa qiyamka caadiga ah.