Asalka magaca "Epitaxial Wafer"

Diyaargarowga wafer wuxuu ka kooban yahay laba tillaabo oo waaweyn: diyaarinta substrate iyo habka epitaxial. Substrate-ka waxa uu ka samaysan yahay semiconductor hal walxo waxaana sida caadiga ah loo farsameeyaa si loo soo saaro qalabka semiconductor. Waxa kale oo ay mari kartaa habaynta epitaxial si loo sameeyo wafer epitaxial. Epitaxy waxa loola jeedaa habka u koraya lakab cusub oo kiristaalo ah oo si taxadar leh loo farsameeyay hal substrate-ka crystal ah. Karistaanka cusubi wuxuu noqon karaa isla shay la mid ah substrate-ka (epitaxy isku mid ah) ama walxo ka duwan (heterogeneous epitaxy). Maadaama lakabka crystal-ka cusub uu u korayo la jaanqaadida jihada substrate's crystal, waxa loo yaqaan lakabka epitaxial. Waferka leh lakabka epitaxial waxaa loo tixraacaa sida wafer epitaxial (epitaxial wafer = lakabka epitaxial + substrate). Qalabka lagu sameeyay lakabka epitaxial waxaa loo yaqaan "epitaxy hore", halka aaladaha lagu sameeyay substrate-ka loo tixraacayo "epitaxy gadaasha," halkaasoo lakabka epitaxial uu u adeego oo kaliya taageero.

Isku-dhafan iyo Epitaxy kala duwan

▪Epitaxy isku mid ah:Lakabka epitaxial iyo substrate waxay ka samaysan yihiin walxo isku mid ah: tusaale, Si/Si, GaAs/GaAs, GaP/GaP.

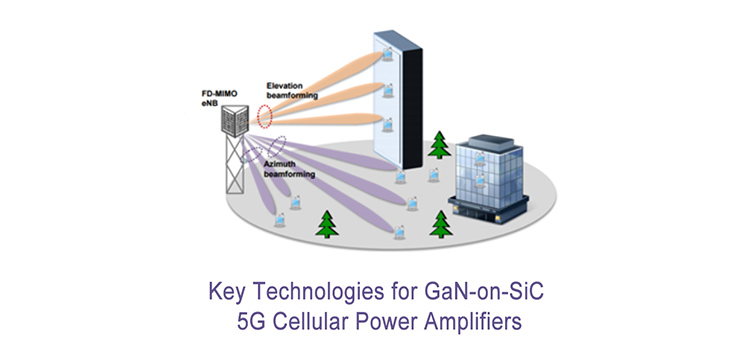

▪Epitaxy kala duwan:Lakabka epitaxial iyo substrate waxay ka samaysan yihiin walxo kala duwan: tusaale, Si/Al₂O₃, GaS/Si, GaAlAs/GaAs, GaN/SiC, iwm.

Wafers la miiray

Dhibaato noocee ah ayay Epitaxy xallisaa?

Alaabada hal-abuurka ah ee ka samaysan kirismaska kaliya kuma filna inay daboolaan baahida sii kordheysa ee kakan ee soo saarista aaladda semiconductor. Sidaa darteed, dabayaaqadii 1959kii, farsamada kobaca walxaha kristaalka ah ee khafiifka ah ee loo yaqaan epitaxy ayaa la sameeyay. Laakiin sidee bay tignoolajiyada epitaxial si gaar ah u caawisay horumarinta agabka? Silicon, horumarka silikoon epitaxy wuxuu dhacay waqti xasaasi ah markii samaynta soo noqnoqoshada sare, transistor-ka awoodda sare leh ay la kulmeen dhibaatooyin la taaban karo. Marka loo eego mabaadi'da transistor-ka, gaaritaanka soo noqnoqoshada sare iyo awoodda waxay u baahan tahay in korantada burburka gobolka ururiyaha uu ahaado mid sarreeya, iyo iska caabbinta taxanaheedu hooseeyo, taasoo la macno ah korantada saturation waa in ay noqotaa mid yar. Midka hore wuxuu u baahan yahay iska caabin sare oo ku jira walxaha aruuriyaha, halka kan dambe uu u baahan yahay iska caabin hoose, taas oo abuureysa khilaaf. Yaraynta dhumucda gobolka ururiyaha si loo yareeyo iska caabbinta taxanaha ah waxay ka dhigi doontaa maraqa silikoon mid aad u khafiif ah oo jilicsan si loo farsameeyo, iyo hoos u dhigista caabbinta waxay ka hor imanaysaa shuruudaha koowaad. Horumarinta tignoolajiyada epitaxial ayaa si guul leh u xalliyey arrintan. Xalku wuxuu ahaa in la kordho lakabka epitaxial resistivity sare ee substrate adkeysi yar. Qalabka waxaa lagu sameeyay lakabka epitaxial, isagoo hubinaya kororka burburka sare ee transistor-ka, halka substrate-ka hooseeya uu hoos u dhigo caabbinta aasaasiga ah wuxuuna hoos u dhigayaa korantada saturation, xallinta iska hor imaadka labada shuruudood.

Intaa waxaa dheer, tignoolajiyada epitaxial ee III-V iyo II-VI semiconductors-ka isku xiran sida GaAs, GaN, iyo kuwa kale, oo ay ku jiraan wajiga uumiga iyo wejiga epitaxy, ayaa arkay horumar la taaban karo. Tignoolajiyadaasi waxay lama huraan u noqdeen samaynta mikrowave badan, optoelectronic, iyo qalab koronto. Gaar ahaan, farsamooyinka sida molecular beam epitaxy (MBE) iyo kaydinta uumiga kiimikada birta-organic (MOCVD) ayaa si guul leh loogu dabaqay lakabyo khafiif ah, superlattices, ceelal quantum, superlatices adag, iyo lakabyo khafiif ah oo atomic ah, oo aasaas adag u ah horumarinta qaybaha cusub ee semiconductor sida "ingineering band."

Codsiyada wax ku oolka ah, inta badan aaladaha semiconductor-ka ballaaran ee ballaaran ayaa lagu sameeyay lakabyada epitaxial, iyadoo walxaha sida silicon carbide (SiC) loo isticmaalo oo keliya sida substrates. Sidaa darteed, xakamaynta lakabka epitaxial waa arrin muhiim u ah warshadaha semiconductor-ka ballaaran.

Tignoolajiyada Epitaxy: Todoba astaamood oo Muhiim ah

1. Epitaxy waxay kori kartaa lakabka iska caabbinta sare (ama hoose) ee hooseeyo (ama sare) substrate iska caabinta.

2. Epitaxy waxay u ogolaataa korriinka N (ama P) nooca epitaxial layers ee nooca P (ama N), si toos ah u samaynta isku-dhafka PN iyada oo aan lahayn arrimaha magdhowga ee soo baxa marka la isticmaalayo faafinta si loo abuuro isku-dhafka PN ee hal substrate crystal.

3. Marka lagu daro tiknoolajiyada maaskarada, kobaca epitaxial ee xulashada ah ayaa lagu samayn karaa meelo gaar ah, taas oo awood u siinaysa samaynta wareegyada isku dhafan iyo qalabka leh qaabab gaar ah.

4. Kobaca Epitaxial wuxuu u oggolaanayaa xakameynta noocyada doping-ka iyo uruurinta, iyada oo awood u leh in lagu gaaro isbeddel degdeg ah ama tartiib tartiib ah ee diiradda.

5. Epitaxy waxay kori kartaa kala duwanaansho, lakabyo badan, iskudhisyo ka kooban qaybo kala duwan, oo ay ku jiraan lakabyo dhuuban.

6. Kobaca Epitaxial wuxuu ku dhici karaa heerkul ka hooseeya barta dhalaalka ee walxaha, oo leh korriin la xakameyn karo, taas oo u oggolaanaysa heerka saxda ah ee atomiga dhumucda lakabka.

7. Epitaxy waxay awood u siisaa kobaca lakabyada crystal-ka ah ee walxaha aan la jiidi karin crystals, sida GaN iyo ternary/quaternary compound semiconductors.

Lakabyada Epitaxial ee kala duwan iyo Habraaca Epitaxial

Marka la soo koobo, lakabyada epitaxial waxay bixiyaan qaab dhismeed si fudud loo xakameyn karo oo qumman marka loo eego substrates bulk, taas oo faa'iido u leh horumarinta alaabta horumarsan.

Waqtiga boostada: Dec-24-2024