Alumina dhoobadamanipulators waxay door muhiim ah ka ciyaaraan warshadaha semiconductor, inta badan loo isticmaalo wareejinta maandooriyaha ee jawi nadiif ah oo sarreeya. Maaddada dhoobada alumina waxay leedahay waxqabad aad u fiican waxayna aad ugu habboon tahay samaynta robots, laakiin dhoobada alumina ma aha oo kaliya walxaha dhoobada leh ee adag ee aad u sarreeya, sidoo kale waa mid aad u adag in la farsameeyo walxaha dhoobada. Semicera Energy Technology Co., Ltd. waa alaab-qeybiye hormuud ah oo ku takhasusay waferka iyo isticmaalka semiconductor-ka horumarsan. Sannado badan ayaan ka shaqaynaynay shaqadan, waxaanan si gaar ah u soo saarnay tignoolajiyada cusub ee farsamaynta ee dhibaatooyinka ka-hortagga ee dhoobada aluminiumka. Wuxuu awooday inuu siiyo macaamiisha alaabada gacanta dhoobada oo tayo leh. Injineerada soo socda ee ka socda Semicera Energy ayaa soo bandhigi doona waxa ay yihiin dhibaatooyinka ku jira saxnaanta mashiinada saxan ee alumina manipulators ceramic.

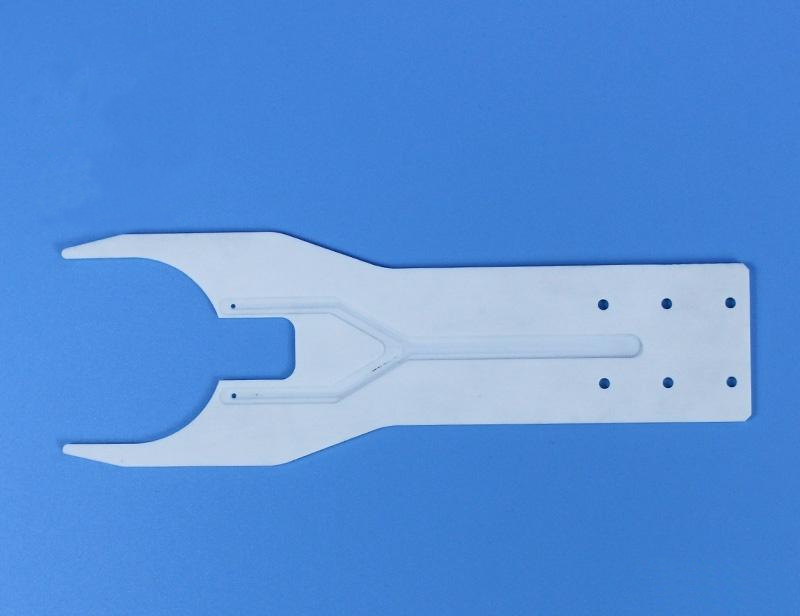

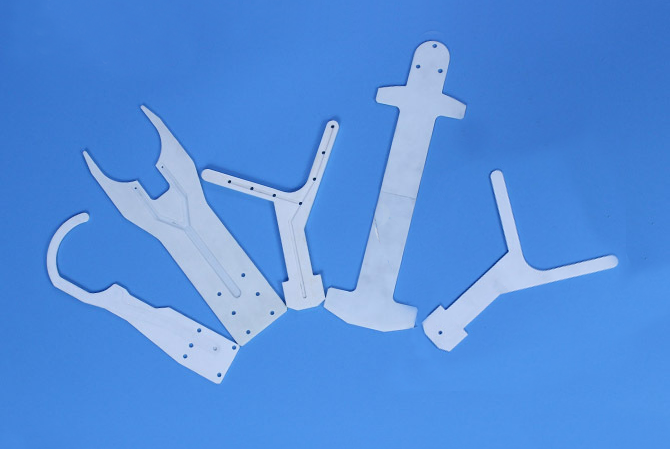

Alumina ceramic cudud robotic

1. Sababtoo ah qallafsanaanta sare ee ceramics alumina, qallafsanaanta qalabka guud ayaa aad uga yar kan dhoobada alumina, wakhtigan waxaan dooran doonaa qalab dheeman ah oo leh qallafsanaan wanaagsan, xitaa sidaas darteed waxay dardar gelin doontaa xirashada qalabka iyo kordhinta qiimaha qalabka; Sidaa darteed, qiimaha saxda ah ee dhoobada alumina ee saxan waa mid aad u sarreeya.

2. Alumina ceramicswaxay leeyihiin xasilooni kulayl wanaagsan, laakiin caabbinta saamaynta waa liidata, jilicsanaantu waa weyn tahay, iyo ifafaale burburka cidhifku waa sahlan tahay in ay dhacdo habka farsamaynta dhoobada alumina; In warshadaha processing, waa in aan samayn noocyo kala duwan oo wanaajinta, laakiin technology processing si weyn ma hagaajin karo heerka u qalmidda alaabta ee manipulator dhoobada alumina.

3. Alumina ceramicslafteedu waxay leedahay shuruudo sare oo loogu talagalay saxnaanta wax qabadsiinta, sidaas darteed farsamaynta dusha sare, xirashada qalabku waxay keenaysaa saxnaanta cabbirka iyo dhimista dhamaystirka dusha sare, haddii workpiece dhoobada uu leeyahay shuruudo sare oo loogu talagalay dhamaystirka dusha sare, waxay u baahan tahay farsamayn dheeraad ah oo polishing, taas oo sidoo kale kordhisa kharashka processing.

4. Alumina dhoobadawax lagu shiido, fududahay in la soo saaro tiro badan oo ah budada dhoobada adag ee adag, budada waa ay fududahay in la weeraro dunta iyo qalabyada kale ee qalabka mashiinka, taasoo keentay in wax soo saarka mashiinka wax soo saarka, dhaawac halis ah qalabka mashiinka. Si loo xalliyo dhibaatadan, Semicera Energy waxay si gaar ah u soo bandhigtay mishiin xardho dhoobo ah oo gaar ah, kaas oo asal ahaan u xaliyay dhibaatadan asal ahaan, saxnaanta farsamaynta shaqada ayaa sidoo kale si weyn loo hagaajiyay. Semicera Energy waxay leedahay faa'iidooyin cad oo ku saabsan mashiinka saxda ah ee manipulator alumina ceramic manipulator, ma aha oo kaliya inuu leeyahay koox farsamo oo xirfad leh, Waxa kale oo jira qalabyo dhammaystiran oo gaar ah oo qalabaynta.

Waqtiga boostada: Sebtembar-04-2023