Lakabka Epitaxial waa hal filim oo crystal ah oo gaar ah oo lagu koray waferka iyada oo loo marayo habka epitaxial, iyo wafer substrate iyo filimka epitaxial waxaa loo yaqaannaa wafer epitaxial. Iyada oo la kordhinayo lakabka silikoon carbide epitaxial substrate silikoon carbide ah, wafer silikoon carbide isku mid ah epitaxial wafer waxaa lagu sii diyaarin karaa diodes Schottky, MOSFETs, IGBTs iyo aaladaha kale ee awooda, oo ay ka mid yihiin substrate 4H-SiC inta badan la isticmaalo.

Sababtoo ah habka wax soo saarka ee kala duwan ee qalabka korontada silikoon carbide iyo qalabka korontada silikoon dhaqameed, si toos ah looguma samayn karo silikoon carbide hal shay oo crystal ah. Qalab dheeri ah oo tayo sare leh oo epitaxial ah waa in lagu beeraa substrate-ka kaliya ee korantada, iyo qalabyo kala duwan waa in lagu soo saaraa lakabka epitaxial. Sidaa darteed, tayada lakabka epitaxial ayaa saameyn weyn ku leh waxqabadka qalabka. Hagaajinta waxqabadka aaladaha awoodeed ee kala duwan ayaa sidoo kale soo bandhigaya shuruudo sare oo loogu talagalay dhumucda lakabka epitaxial, xoojinta doping iyo cilladaha.

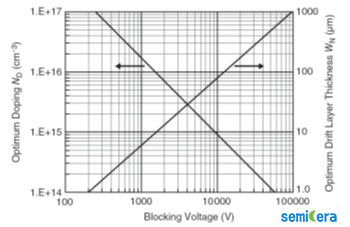

FIG 1. Xiriirka ka dhexeeya fiirsashada doping iyo dhumucda lakabka epitaxial ee aaladda unipolar iyo xannibaadda korantada

Hababka diyaarinta ee lakabka epitaxial SIC inta badan waxaa ka mid ah habka koritaanka uumi-baxa, koritaanka wajiga dareeraha epitaxial (LPE), korriinka molecular beam epitaxial koritaanka (MBE) iyo kayd kiimikaad uumiga (CVD). Waqtigan xaadirka ah, kaydinta uumiga kiimikada (CVD) waa habka ugu muhiimsan ee loo isticmaalo wax soo saarka baaxadda leh ee warshadaha.

| Habka diyaarinta | Faa'iidooyinka habka | Khasaaraha nidaamka |

|

Kobaca Epitaxial Wajiga dareeraha ah

(LPE)

|

Shuruudaha qalabka fudud iyo hababka korriinka qiimaha jaban. |

Way adag tahay in la xakameeyo qaab-dhismeedka dusha sare ee lakabka epitaxial. Qalabku isku mar ma wada saari karaan wafers badan, taas oo xaddidaysa wax soo saarka tirada badan. |

|

Kobaca Epitaxial Beam Molecular Beam (MBE)

|

Lakabyada SiC crystal epitaxial ee kala duwan ayaa lagu kori karaa heerkulka koritaanka hooseeya |

Shuruudaha vacuum qalabku waa qaali waana qaali. Heerka kobaca ee lakabka epitaxial oo gaabis ah |

|

Dhigista Uumiga Kiimikada (CVD) |

Habka ugu muhiimsan ee wax soo saarka ballaaran ee warshadaha. Heerka kobaca si sax ah ayaa loo xakameyn karaa marka la korayo lakabyada epitaxial ee dhumucsan. |

Lakabyada SiC epitaxial ayaa weli leh cillado kala duwan kuwaas oo saameeya sifooyinka qalabka, markaa habka koritaanka epitaxial ee SiC wuxuu u baahan yahay in si joogto ah loo hagaajiyo.TaCloo baahan yahay, eeg SemiceraAlaabta TaC) |

|

Habka koritaanka uumiga

|

Isticmaalka qalab la mid ah sida jiidashada kiristaalka ee SiC, nidaamku wax yar ayuu ka duwan yahay soo jiidashada crystal. Qalab qaan-gaar ah, qiimo jaban |

Uumi-baxa aan sinnayn ee SiC ayaa ka dhigaysa mid adag in laga faa'iidaysto uumiga si ay u koraan lakabyo epitaxial oo tayo sare leh |

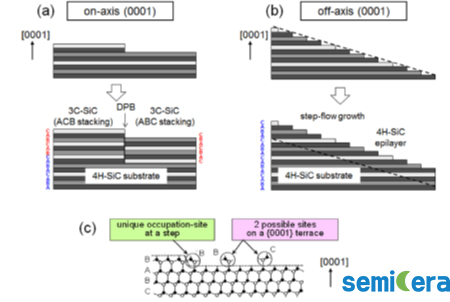

FIG 2. Isbarbardhigga hababka diyaarinta ugu muhiimsan ee lakabka epitaxial

Dhinaca dhidibka ka baxsan {0001} substrate leh xagal janjeero gaar ah, sida ku cad Jaantuska 2(b), cufnaanta salladu waa ka weyn tahay, cabbirka oogada tallaabaduna way ka yar tahay, nukleemka crystal-ka ma fududa in la sameeyo. Waxay ku dhacaan dusha sare ee tallaabada, laakiin marar badan waxay ku dhacdaa barta isku dhafka ah ee tallaabada. Xaaladdan oo kale, waxaa jira hal fure oo nukliyeer ah. Sidaa darteed, lakabka epitaxial wuxuu si fiican u soo celin karaa nidaamka isku dhejinta ee substrate-ka, taas oo meesha ka saaraysa dhibaatada wada noolaanshaha noocyada badan.

FIG 3. Jaantuska habsocodka jireed ee 4H-SiC habka xakamaynta tallaabada epitaxy

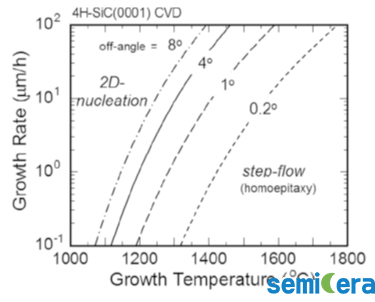

FIG 4. Xaaladaha halista ah ee kobaca CVD ee habka 4H-SiC ee habka epitaxy-ku-xakamaynta

FIG 5. Isbarbardhigga heerarka kobaca ee hoos yimaada ilo silikoon oo kala duwan ee 4H-SiC epitaxy

Waqtigan xaadirka ah, tignoolajiyada epitaxy ee silikoon carbide waa mid ku bislaaday codsiyada korantada hooseeya iyo kuwa dhexdhexaadka ah (sida 1200 volt). Labbiska dhumucda, lebbiska fiirsashada doping iyo qaybinta cilladda lakabka epitaxial waxay gaari kartaa heer aad u wanaagsan, kaas oo asal ahaan dabooli kara baahiyaha korantada dhexe iyo hoose ee SBD (Schottky diode), MOS (xajmiga oxide semiconductor field effect transistor), JBS ( isku xirka diode) iyo aaladaha kale.

Si kastaba ha ahaatee, goobta cadaadiska sare, wafers epitaxial ayaa weli u baahan inay ka gudbaan caqabado badan. Tusaale ahaan, aaladaha u baahan inay u adkeystaan 10,000 volts, dhumucda lakabka epitaxial wuxuu u baahan yahay inuu ahaado qiyaastii 100μm. Marka la barbardhigo aaladaha korantada hooseeya, dhumucda lakabka epitaxial iyo isku-duubnaanta fiirsashada doping ayaa aad uga duwan, gaar ahaan isku-duubnaanta feejignaanta doping. Isla mar ahaantaana, cilladda saddexagalka ah ee lakabka epitaxial waxay sidoo kale burburin doontaa waxqabadka guud ee qalabka. Codsiyada korantada sare leh, noocyada aaladaha waxay u muuqdaan inay isticmaalaan aaladaha laba-cirifoodka, kuwaas oo u baahan nolosha dadka laga tirada badan yahay ee lakabka epitaxial, markaa geeddi-socodku wuxuu u baahan yahay in la hagaajiyo si loo hagaajiyo nolosha dadka tirada yar.

Waqtigan xaadirka ah, epitaxy-ga gudaha inta badan waa 4 inji iyo 6 inch, iyo saamiga xajmiga weyn ee silikoon carbide epitaxy ayaa sii kordhaya sanadba sanadka ka dambeeya. Baaxadda xaashida silikoon carbide epitaxial waxaa inta badan ku xaddidan cabbirka substrate-ka silikoon carbide. Waqtigan xaadirka ah, 6-inch substrate silicon carbide substrate waa la baayacmushtareeyay, marka silikoon carbide epitaxial wuxuu si tartiib tartiib ah uga gudbayaa 4 inji ilaa 6 inji. Iyadoo horumarinta joogtada ah ee tignoolajiyada diyaarinta substrate-ka silikoon carbide iyo balaarinta awooda, qiimaha substrate carbide silikoon ayaa si tartiib tartiib ah hoos u dhacaya. Isku dhafka qiimaha xaashida epitaxial, substrate-ku wuxuu xisaabiyaa in ka badan 50% qiimaha, sidaas darteed hoos u dhaca qiimaha substrate-ka, qiimaha silikoon carbide epitaxial ayaa sidoo kale la filayaa inuu hoos u dhaco.

Waqtiga boostada: Jun-03-2024