Hal Muuqaal

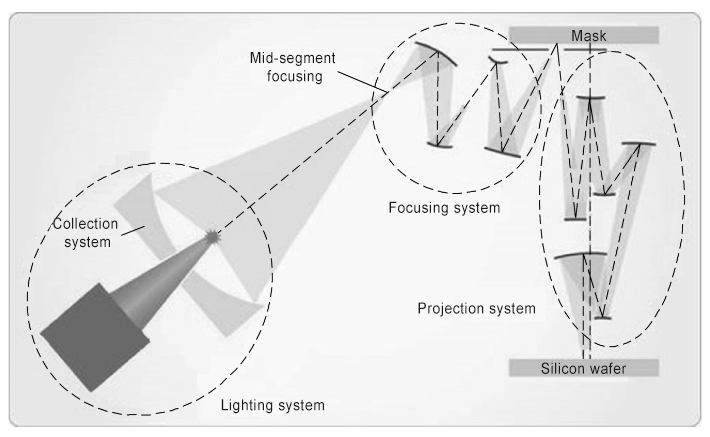

Habka wax soo saarka wareegga isku dhafan, sawir-qaadista waa habka asaasiga ah ee go'aaminaya heerka isdhexgalka ee wareegyada isku dhafan. Hawsha geeddi-socodkani waa in si daacad ah loo gudbiyo oo loo wareejiyo macluumaadka garaafyada wareegga maaskarada (sidoo kale loo yaqaan maaskaro) substrate-ka walxaha semiconductor.

Mabda'a aasaasiga ah ee geeddi-socodka sawir-qaadista waa in la isticmaalo fal-celinta sawir-qaadista ee sawir-qaadaha ee lagu daboolay dusha sare ee substrate-ka si loo duubo qaabka wareegga ee maaskarada, taas oo lagu gaaro ujeedada wareejinta qaabka wareegga isku dhafan ee naqshadeynta ilaa substrate-ka.

Habka aasaasiga ah ee sawir-qaadista

Marka hore, photoresist waxaa lagu dabaqaa dusha sare ee substrate iyadoo la adeegsanayo mashiinka daahan;

Ka dib, mashiinka sawir-qaadista ayaa loo isticmaalaa si loo soo bandhigo substrate-ka lagu daboolay sawir-qaadista, iyo habka fal-celinta photochemical waxaa loo isticmaalaa in lagu duubo macluumaadka qaabka maaskarada ee uu gudbiyo mashiinka sawir-qaadista, buuxinta gudbinta daacadnimada, wareejinta iyo ku-celinta qaabka maaskarada ee substrate;

Ugu dambeyntii, horumariye ayaa loo isticmaalaa si loo horumariyo substrate-ka bannaan si meesha looga saaro (ama u hayo) sawir-qaadista ee ku dhacda fal-celinta sawir-kiimikada ka dib soo-gaadhista.

Habka sawir-qaadista labaad

Si loo wareejiyo qaabka wareegga ee loogu talagalay maaskarada silikoon wafer, wareejinta waa in marka hore lagu gaaraa habka soo-gaadhista, ka dibna qaabka silikoon waa in lagu helaa habka xoqidda.

Maaddaama iftiiminta aagga geeddi-socodka sawir-qaadista ay isticmaasho isha iftiinka jaalaha ah kaas oo walxaha sawir-qaadista ay yihiin kuwo aan dareen lahayn, waxaa sidoo kale loo yaqaannaa aagga iftiinka jaalaha ah.

Sawir-qaadista ayaa markii ugu horreysay loo adeegsaday warshadaha daabacaadda waxayna ahayd tignoolajiyada ugu weyn ee wax soo saarka PCB-ga hore. Laga soo bilaabo 1950-meeyadii, sawir-qaadista ayaa si tartiib tartiib ah u noqotay tignoolajiyada guud ee wareejinta hannaankii wax soo saarka IC.

Tilmaamaha ugu muhiimsan ee habka lithography waxaa ka mid ah xallinta, dareenka, saxnaanta dulsaarka, heerka cilladda, iwm.

Waxyaabaha ugu muhiimsan ee habka sawir-qaadista waa sawir-qaadista, taas oo ah walxo sawir leh. Maaddaama dareenka sawir-qaadaha ay ku xiran tahay hirarka dhererka isha iftiinka, agabka sawir-celinta ee kala duwan ayaa looga baahan yahay hababka sawir-qaadista sida khadka g/i, 248nm KrF, iyo 193nm ArF.

Habka ugu muhiimsan ee habka sawir-qaadista caadiga ah waxaa ka mid ah shan tallaabo

:

-Diyaarinta filimka salka;

-Codso sawir qaade iyo dubi jilicsan;

-Isku toosinta, soo-gaadhista iyo dubista soo-gaadhista ka dib;

- Samee filim adag;

-In la ogaado horumarka.

(1)Diyaarinta filimka saldhiga: inta badan nadiifinta iyo fuuqbaxa. Sababtoo ah wax kasta oo wasakhaysan ayaa daciifin doona isku-xidhka u dhexeeya sawir-qaadaha iyo maraqa, nadiifinta dhamaystiran waxay hagaajin kartaa isku-xidhka u dhexeeya waferka iyo sawir-qaadiyaha.

(2)Daahan Photoresisist: Tan waxaa lagu gaaraa in la beddelo waferka silikoon. Sawir-qaadayaasha kala duwan waxay u baahan yihiin cabbirro habraaca daahan oo kala duwan, oo ay ku jiraan xawaaraha wareegga, dhumucda sawir-qaadista, iyo heerkulka.

Dubidda jilicsan: Dubidu waxay hagaajin kartaa isku-xidhka u dhexeeya sawir-qaadista iyo wafer silikoon, iyo sidoo kale isku-dhafka dhumucda sawir-qaadista, taas oo faa'iido u leh xakamaynta saxda ah ee cabbirada joomatari ee habka xiga ee xoqidda.

(3)Toosinta iyo soo-gaadhista: Isku toosinta iyo soo-gaadhista ayaa ah tillaabooyinka ugu muhiimsan ee habka sawir-qaadista. Waxay tixraacayaan in la waafajiyo qaabka maaskarada iyo qaabka jira ee waferka (ama qaabka lakabka hore), ka dibna ku iftiiminaya iftiin gaar ah. Tamarta iftiinka waxay dhaqaajisaa qaybaha sawir-qaadista ee sawir-qaadaha, taas oo u wareejinaysa qaabka maaskarada sawir-qaadaha.

Qalabka loo isticmaalo isku-habaynta iyo soo-gaadhista waa mashiinka sawir-qaadista, kaas oo ah qalabka ugu qaalisan ee hal-abuurka ah ee habka wax-soo-saarka wareegga isku-dhafka ah. Heerka farsamada ee mashiinka sawir-qaadista ayaa u taagan heerka horumarinta dhammaan khadka wax soo saarka.

Dubidda soo-gaadhista ka dib: waxa loola jeedaa habka dubista gaaban ka dib soo-gaadhista, kaas oo leh saamayn ka duwan kan qoto dheer ee ultraviolet photoresists iyo sawir-celinta caadiga ah ee i-line.

Wixii sawir-qaadista qoto dheer ee ultraviolet, dubista soo-gaadhista ka dib waxay ka saartaa qaybaha difaaca ee sawir-qaadaha, taas oo u oggolaanaysa sawir-qaaduhu inuu ku milmo horumariyaha, markaa dubista soo-gaadhista ka dib waa lagama maarmaan;

Sawir-qaadaha caadiga ah ee i-line, dubista soo-gaadhista ka dib waxay hagaajin kartaa dhejinta sawir-qaadaha waxayna yareyn kartaa hirarka taagan (mawjadaha taagan waxay saameyn xun ku yeelan doonaan morphology cidhifka sawir-qaadaha).

(4)Horumarinta filimka adagIsticmaalka horumariyaha si aad u milmiso qaybta milmay ee sawir-qaadaha (photoresist togan) ka dib soo-gaadhista, oo si sax ah u muuji qaabka maaskarada oo leh qaabka sawir-qaadista.

Qodobbada muhiimka ah ee habka horumarinta waxaa ka mid ah heerkulka horumarinta iyo waqtiga, qiyaasta horumarinta iyo xoojinta, nadiifinta, iwm. Iyadoo la hagaajinayo cabbirada ku habboon horumarinta, farqiga u dhexeeya qaybaha kala-soocida iyo qaybaha aan la daboolin ee photoresist waa la kordhin karaa, sidaas darteed helitaanka saamaynta horumarineed ee la rabo.

Adkeynta waxaa sidoo kale loo yaqaan dubista qallafsanaan, taas oo ah habka ka saarista dareeraha haray, horumariyaha, biyaha iyo qaybaha kale ee aan loo baahnayn ee ku jira photoresisist ee horumarsan ee kuleylka iyo uumi-baxa, si loo hagaajiyo xabagta photoresist ee substrate silicon iyo iska caabinta etching ee sawir qaade.

Heerkulka habka qallafsanaantu wuu kala duwan yahay iyadoo ku xiran tahay sawir-qaadayaasha kala duwan iyo hababka adkeynta. Dhismuhu waa in qaabka sawir-qaadista uusan qaab-mayn oo sawir-qaaduhu waa in si adag loo sameeyaa.

(5)Kormeerka horumarintaTani waa si loo hubiyo cilladaha qaabka sawir-qaadista ka dib koriinka. Caadi ahaan, tignoolajiyada aqoonsiga sawirka waxaa loo isticmaalaa in si toos ah loo sawiro qaabka chip ka dib horumarka oo lala barbar dhigo qaabka caadiga ah ee aan cillad lahayn ee horay loo kaydiyay. Haddii wax farqi ah la helo, waxaa loo arkaa mid cilladaysan.

Haddii tirada cilladaha ay dhaafto qiimo gaar ah, waferka silikoon waxaa lagu qiimeeyaa inuu ku guuldareystay imtixaanka horumarinta waxaana laga yaabaa in la tirtiro ama dib loo shaqeeyo sida ku habboon.

Habka wax-soo-saarka wareegga isku-dhafka ah, geeddi-socodka intooda badani waa kuwo aan la bedeli karin, sawir-qaadista waa mid ka mid ah hababka aadka u yar ee dib loo habeyn karo.

Saddex sawir-maskaxeed iyo agab sawir-celin

3.1 Sawir qaade

Maaskarada sawir-qaadista, oo sidoo kale loo yaqaan maaskaro sawir-qaadista, waa sayid loo isticmaalo habka sawir-qaadista ee wax-soo-saarka wafer-wareegga isku-dhafan.

Habka wax-soo-saarka sawir-qaadista waa in loo beddelo xogta qaabeynta asalka ah ee looga baahan yahay wax-soo-saarka wafer-ka oo ay naqshadeeyeen injineerada naqshadaynta wareegga isku-dhafka ah qaab xog ah oo lagu aqoonsan karo koronto-dhaliyeyaasha qaabka laysarka ama qalabka soo-gaadhista alwaax elektarooniga ah iyada oo loo marayo farsamaynta xogta maaskaro, si ay u soo baxdo qalabka kor ku xusan ee maaddada sawir-maskaxeed ee lagu dahaadhay walxaha sawir-qaadista; ka dib waxaa lagu farsameeyaa iyada oo loo marayo habab taxane ah sida horumarinta iyo xoqidda si loo hagaajiyo qaabka alaabta substrate; ugu dambeyntii, waa la kormeeraa, la dayactiray, la nadiifiyaa, iyo filim-ku dahaadhay si loo sameeyo badeeco maaskaro ah waxaana loo geeyaa soo saaraha wareegga isku dhafan si loogu isticmaalo.

3.2 Photoresisist

Photoresist, oo sidoo kale loo yaqaan 'photoresist', waa walxo sawir leh. Qaybaha sawir-qaadista ee ku dhex jira waxay mari doonaan isbeddel kiimiko ah oo hoos yimaada shucaaca iftiinka, taas oo keenta isbeddel ku yimaada heerka kala dirida. Shaqadeeda ugu weyn waa in lagu wareejiyo qaabka maaskarada oo loo wareejiyo substrate sida maraqa.

Mabda'a shaqada ee sawir-qaadista: Marka hore, sawir-qaadaha waxaa lagu dahaadhay substrate-ka oo horay loo dubay si looga saaro dareeraha;

Marka labaad, maaskarada ayaa soo ifbaxda iftiinka, taasoo keenaysa qaybaha sawir-qaadista ee qaybta bannaanka si ay u maraan fal-celin kiimikaad;

Kadibna, dubista soo-gaadhista ka dib ayaa la sameeyaa;

Ugu dambeyntii, photoresist qayb ahaan waa la kala diraa iyada oo loo marayo horumarinta (photoresist togan, aagga bannaanka ah waa la kala diraa; sawir-celinta taban, aagga aan la daboolin waa la kala diraa), taas oo ogaanaysa wareejinta qaabka wareegga isku dhafan ee maaskarada ilaa substrate.

Qaybaha sawir-qaadista inta badan waxaa ka mid ah xabagta-samaynta filimada, qaybta sawir-qaadista, waxyaabaha lagu daro raadraaca iyo dareeraha.

Waxaa ka mid ah, resin-samaynta filimka waxaa loo isticmaalaa in lagu bixiyo sifooyin farsamo iyo caabbinta etching; Qaybta sawir-qaadista waxay ku dhacdaa isbeddel kiimikaad iftiinka hoostiisa, taasoo keenta isbeddel ku yimaada heerka kala dirida;

Waxyaabaha lagu daro raadraaca waxaa ka mid ah dheeha, xoojiyayaasha viscosity, iwm, kuwaas oo loo isticmaalo in lagu wanaajiyo waxqabadka sawir-qaadista; dareerayaasha waxaa loo isticmaalaa in lagu milo qaybaha oo si siman loo walaaqo.

Photoresists-yada hadda loo isticmaalo ballaaran waxaa loo qaybin karaa sawir-qaade dhaqameed iyo sawir-qaade kiimiko ahaan la xoojiyay iyadoo loo eegayo habka fal-celinta photochemical, waxaana sidoo kale loo qaybin karaa ultraviolet, ultraviolet qoto dheer, ultraviolet daran, iftiinka elektarooniga ah, ion beam iyo sawir-qaadayaasha raajada sida waafaqsan hirarka dhererka sawir-qaadista.

Afar qalab sawir qaade

Tignoolajiyada sawir-qaadista ayaa soo martay habka horumarinta ee xiriirinta/lithography-ga dhow, lithography saadaalinta indhaha, lithography-tillaabada-iyo-ku-celcelinta, sawir-qaadista, sawir-qaadista, immersion lithography, iyo lithography EUV.

4.1 Mashiinka Lithography ee Xiriirka/Udhowaanshaha

Tignoolajiyada lithography ee xiriirka waxay soo muuqatay 1960-meeyadii waxaana si weyn loo isticmaali jiray 1970-yadii. Waxay ahayd habka lithography-ga ugu weyn ee xilligii wareegyada isku dhafan ee cabbirka yar waxaana inta badan loo isticmaali jiray in lagu soo saaro wareegyo isku dhafan oo cabbirkoodu ka weyn yahay 5μm.

Mashiinka lithography ee xidhiidhka/u dhowaanshaha, maraqa waxaa sida caadiga ah lagu dhejiyaa meel toosan oo gacanta lagu hayo iyo miiska shaqada oo wareegta. Hawl-wadeenku waxa uu isticmaalaa mikroskoob meel gaar ah si uu isku mar u eego booska maaskaro iyo wafer, oo uu gacanta ku xakameeyo booska miiska shaqada si uu isu waafajiyo maaskarada iyo maraqa. Ka dib markii waferka iyo maaskarada la isku toosiyo, labada ayaa la isku cadaadi doonaa si maaskarku uu si toos ah ula xiriiro sawir-qaadaha dusha sare ee waferka.

Ka dib marka la saaro ujeeddada mikroskoobyada, maraqa la riixay iyo maaskarada ayaa loo rari doonaa miiska soo-gaadhista si ay u soo bandhigto. Iftiinka ka soo baxaya laambada meerkurigu waa isku dhaceen oo barbar socda maaskarada iyadoo loo marayo muraayad. Maaddaama maaskarku si toos ah ula xiriiro lakabka sawir-qaadista ee wafer, qaabka maaskarada waxaa loo wareejiyaa lakabka sawir-qaadista ee saamiga 1: 1 ka dib soo-gaadhista.

Qalabka xiriirinta lithography waa kan ugu fudud uguna dhaqaalaha badan qalabka litography indhaha, wuxuuna gaari karaa soo bandhigida sawirada cabbirka qaab-hoosaadka, sidaa darteed wali waxaa loo isticmaalaa wax soo saarka dufcada yar iyo cilmi baarista shaybaarka. Wax soo saarka wareegga isku dhafan ee baaxadda weyn, tignoolajiyada lithography ee u dhow ayaa la soo bandhigay si looga fogaado kororka kharashyada lithography ee ay sababto xiriirka tooska ah ee u dhexeeya maaskarada iyo waferka.

Lithography dhowaanshaha ayaa si weyn loo isticmaalay sannadihii 1970-meeyadii intii lagu jiray xilligii wareegyada isku-dhafan ee-yar-yar iyo xilligii hore ee wareegyada isku-dhafan ee dhexdhexaadka ah. Si ka duwan lithography-ga xidhiidhka, maaskarada ku jirta lithography dhow maaha mid si toos ah ula xidhiidha sawir-qaadaha waferka, laakiin farqiga ay ka buuxaan nitrogen ayaa hadhay. Maaskarku wuxuu ku dul sabeeyaa nitrogen-ka, cabbirka farqiga u dhexeeya maaskarada iyo waferka waxaa lagu go'aamiyaa cadaadiska nitrogen.

Maaddaama aysan jirin xiriir toos ah oo ka dhexeeya waferka iyo maaskarada ee u dhow lithography, cilladaha la soo bandhigay inta lagu jiro habka lithography waa la yareeyaa, taas oo yareyneysa luminta maaskarada iyo hagaajinta dhalidda wafer. Lithography ee u dhow, farqiga u dhexeeya waferka iyo maaskarada ayaa dhigaya waferka gobolka Fresnel diffraction. Joogitaanka diffraction ayaa xaddidaya hagaajinta dheeraadka ah ee xallinta qalabka lithography ee u dhow, sidaas awgeed tignoolajiyadani waxay inta badan ku habboon tahay soo saarista wareegyada isku dhafan oo leh cabbirro muuqaal ah oo ka sarreeya 3μm.

4.2 Stepper iyo ku celiyaha

Stepper-ku waa mid ka mid ah qalabka ugu muhiimsan taariikhda wafer lithography, kaas oo kor u qaaday habka lithography-yar ee wax-soo-saarka ballaaran. Stepper-ku waxa uu isticmaalaa goob soo-gaadhis ah oo caadi ah oo ah 22mm × 22mm iyo muraayad saadaasha indhaha ah oo leh saamiga dhimista 5:1 ama 4:1 si loogu wareejiyo qaabka maaskarada maraqa.

Mashiinka-lithography-ga ee tallaabada-iyo-ku-celcelinta guud ahaan wuxuu ka kooban yahay nidaam-hoosaad hoosaadyo, hab-hoosaad-hoosaadka shaqada, nidaamka-hoosaadka maaskaro, hab-hoosaadka diiradda/heeraynta, hab-hoosaadka toosinta, hab-hoosaadka qaab-hoosaadka, hab-hoosaadka wareejinta wafer, qayb hoosaadka wareejinta maaskaro , Nidaam hoosaadyo elektaroonig ah, iyo nidaam-hoosaad software.

Habka shaqada ee caadiga ah ee mashiinka lithography-ku-cel-celinta waa sida soo socota:

Marka hore, waferka lagu daboolay sawir qaade waxaa loo wareejiyaa miiska shaqada iyadoo la adeegsanayo nidaamka hoosaadka wareejinta wafer, iyo maaskarada la soo bandhigayo waxaa loo wareejiyaa miiska maaskaro iyadoo la adeegsanayo nidaamka hoosaadka wareejinta maaskaro;

Kadibna, nidaamku wuxuu isticmaalaa nidaamka hoosaadka diirada / heerka si uu u sameeyo cabbirka dhererka-dhibcaha badan ee wafer ee marxaladda workpiece si loo helo macluumaadka sida dhererka iyo xagasha foorarsiga ee dusha sare ee wafer si loo soo bandhigo, si aagga soo-gaadhista waferka waxaa mar walba lagu xakameyn karaa gudaha qoto dheer ee ujeeddada saadaasha inta lagu jiro habka soo-gaadhista;Ka dib, nidaamku wuxuu isticmaalaa nidaamka hoose ee toosinta si uu u waafajiyo maaskarada iyo waferka si inta lagu jiro habka soo-gaadhista saxnaanta booska sawirka maaskarada iyo wareejinta qaabka waferka ayaa had iyo jeer ku jira shuruudaha dulsaarka.

Ugu dambeyntii, tallaabada-qaadista-iyo-soo-bandhigga ee dhammaan dusha sare ee wafer-ka ayaa la dhammeeyaa iyadoo loo eegayo dariiqa loo qoondeeyey si loo xaqiijiyo shaqada wareejinta qaabka.

Tijaabada soo socota iyo mishiinka sawir-qaadista sawir-qaadista waxay ku salaysan tahay habka shaqada ee aasaasiga ah ee kor ku xusan, hagaajinta tillaabooyinka → soo-gaadhista iskaanka → soo-gaadhista, iyo diiradda-saarista → toosinta soo bandhigid is barbar socda.

Marka la barbar dhigo mishiinka sawir-qaadista-tallaabo-iyo-soo-celinta, mishiinka-lithography-ga ee tallaabada-iyo-ku-cel-celinta uma baahna inuu gaadho iskaanka gadaal-ka-beddelka ee maaskarada iyo maraqyada, uma baahna miis-ka-qaadista iyo nidaamka xakamaynta iskaanka isku-dhafka ah. Sidaa darteed, qaab-dhismeedku waa mid fudud, kharashkuna waa mid hooseeya, hawlgalkuna waa mid la isku halleyn karo.

Ka dib markii tignoolajiyada IC ay soo gashay 0.25μm, adeegsiga tillaabada-iyo-ku-celinta lithography-ga ayaa bilaabay inay hoos u dhacdo iyadoo ay ugu wacan tahay faa'iidooyinka lithography-ka-iyo-scan ee sawirka cabbirka goobta soo-gaadhista iyo isku-duubnaanta soo-gaadhista. Hadda, tillaabada-iyo-ku-celcelinta lithography-gii ugu dambeeyay ee ay bixiso Nikon waxay leedahay muuqaal soo-bandhigis taagan oo la mid ah kan lit-ography-ka-iyo-scan-ka, waxayna farsamayn kartaa in ka badan 200 wafers saacaddii, oo leh wax-soo-saar aad u sarreeya. Noocan mishiinka lithography ayaa hadda inta badan loo isticmaalaa soo saarista lakabyada IC ee aan muhiimka ahayn.

4.3 Scanner Stepper

Codsiga tillaabo-iyo-scan-gacan-qaadista waxay bilaabatay 1990-meeyadii. Marka la habeeyo ilaha iftiinka soo-gaadhista ee kala duwan, tignoolajiyada-tallaabo-iyo-scan waxay taageeri kartaa noodhka tignoolajiyada ee kala duwan, laga bilaabo 365nm, 248nm, 193nm immersion ilaa lithography EUV. Si ka duwan tillaabada-iyo-ku-cel-celinta lithography, soo-gaadhista hal-goob ee tillaabo-iyo-scan-lithography waxay qabataa iskaanka firfircoon, taas oo ah, saxanadda maaskaro waxay dhamaystirtaa dhaqdhaqaaqa iskaanka si isku mid ah marka loo eego waferka; ka dib markii soo-gaadhista berrinka hadda la dhammeeyo, waferka waxaa lagu qaadaa marxaladda workpiece wuxuuna u tallaabay booska iskaanka ee soo socda, soo-gaadhista soo noqnoqda ayaa sii socota; ku celi soo-gaadhista-tallaabo-iyo-sawir-gaarsiinta dhawr jeer ilaa dhammaan meelaha maraqyada waferka oo dhan ay soo ifbaxayaan.

Marka la habeeyo noocyada kala duwan ee ilaha iftiinka (sida i-line, KrF, ArF), scanner stepper-scanner wuxuu taageeri karaa ku dhawaad dhammaan qanjidhada tignoolajiyada ee habka-dhamaadka hore ee semiconductor. Nidaamyada CMOS-ku-saleysan ee silikoon-ku-saleysan ee caadiga ah waxay qaateen sawir-qaadayaal tiro badan tan iyo 0.18μm node; Mashiinnada lithography ee ultraviolet-ka daran (EUV) ee hadda loo isticmaalo qanjidhada habraaca ee ka hooseeya 7nm sidoo kale waxay adeegsadaan sawir-qaadista stepper. Ka dib markii qayb ka mid ah wax ka beddelka la qabsiga, stepper-scanner wuxuu sidoo kale taageeri karaa cilmi baarista iyo horumarinta iyo soo saarista habab badan oo aan silikoon ku saleysneyn sida MEMS, qalabka korontada, iyo qalabka RF.

Soosaarayaasha ugu waaweyn ee mashiinada saadaasha tilaabo-iyo-scan waxaa ka mid ah ASML (Netherlands), Nikon (Japan), Canon (Japan) iyo SMEE (Shiinaha). ASML waxay bilawday taxanaha TWINSCAN ee mishiinnada lithography-ka ee tallaabo-iyo-scan. Waxay qabataa qaab-dhismeedka nidaamka laba-heer, kaas oo si wax ku ool ah u wanaajin kara heerka wax soo saarka qalabka oo noqday mashiinka lithography-dhamaadka ugu badan ee la isticmaalo.

4.4 Immersion Lithography

Waxa laga arki karaa qaacidada Rayleigh in, marka mawjada dhererka gaadhista aan isbeddelin, hab wax ku ool ah oo lagu sii wanaajin karo xallinta sawir-qaadista ayaa ah in la kordhiyo daloolka nambarada ee nidaamka sawirka. Xallinta sawir-qaadista ee ka hooseeya 45nm iyo ka sare, habka soo-gaadhista qalalan ee ArF ma buuxin karto shuruudaha (maxaa yeelay waxay taageertaa xallinta sawirka ugu badan ee 65nm), markaa waa lagama maarmaan in la soo bandhigo habka lithography immersion. Tignoolajiyada qadiimiga ah, dhexdhexaadinta u dhaxaysa lens-ka iyo sawir-qaadaha waa hawo, halka tignoolajiyada lithography-ga immersion ay ku beddesho dhexdhexaadiyaha hawada dareere (sida caadiga ah biyaha ultrapure leh index refractive of 1.44).

Dhab ahaantii, tignoolajiyada lithography immersion waxay isticmaashaa gaabinta mawjadaha dhererka isha iftiinka ka dib marka iftiinku dhex maro dhexdhexaadiyaha dareeraha ah si loo hagaajiyo xallinta, saamiga gaabintuna waa index refractive ee dhexdhexaadiyaha dareeraha ah. In kasta oo mishiinka lithography-ga immersion uu yahay nooc ka mid ah mishiinka lithography-ka ee tallaabo-iyo-scan, iyo nidaamka qalabkiisa xalkiisu isma beddelin, waa wax ka beddelka iyo balaadhinta mishiinka lithography-ka-iyo-scan ee ArF sababtoo ah hordhaca tignoolajiyada muhiimka ah ee la xidhiidha. in la quusiyo.

Faa'iidada lithography immersion waa, iyadoo ay ugu wacan tahay kororka daloolka nambarada ee nidaamka, awoodda xallinta sawir-qaadista ee mashiinka lithography-scanner waa la wanaajiyey, kaas oo buuxin kara shuruudaha habka ee xallinta sawirada ee ka hooseeya 45nm.

Maadaama mashiinka lithography immersion uu wali isticmaalo isha iftiinka ArF, sii wadida hawsha waa la dammaanad qaaday, iyadoo la badbaadinayo qiimaha R&D ee isha iftiinka, qalabka iyo habka. Iyada oo ku saleysan, oo ay weheliso garaafyo badan iyo tignoolajiyada xisaabinta xisaabinta, mishiinka lithography-ga ayaa loo isticmaali karaa qanjidhada habraaca ee 22nm iyo ka hooseeya. Ka hor inta aan mashiinka lithography EUV si rasmi ah loo gelin wax soo saarka ballaaran, mishiinka lithography immersion ayaa si weyn loo isticmaalay oo buuxin kara shuruudaha habka ee 7nm node. Si kastaba ha noqotee, iyadoo ay ugu wacan tahay soo bandhigida dareeraha immersion, dhibka injineernimada ee qalabka laftiisa ayaa si weyn u kordhay.

Farsamooyinkeeda muhiimka ah waxaa ka mid ah sahayda dareeraha dareeraha ah iyo tignoolajiyada soo kabashada, tignoolajiyada dayactirka goobta dareeraha, wasakhowga lithography iyo tignoolajiyada xakamaynta cilladaha, horumarinta iyo dayactirka lensyada saadaasha godka tirooyinka aadka u weyn, iyo tignoolajiyada ogaanshaha tayada sawirida ee hoos yimaada xaaladaha immersion.

Waqtigan xaadirka ah, mashiinnada sawir-qaadista-iyo-scan ee ArFi-ganacsiga ah waxaa inta badan bixiya laba shirkadood, oo kala ah ASML oo Nederlaan ah iyo Nikon oo Japan ah. Waxaa ka mid ah, qiimaha hal ASML NXT1980 Di waa qiyaastii 80 milyan oo Yuuro.

4.5 Mashiinka Lithography Ultraviolet ee daran

Si loo hagaajiyo xallinta sawir-qaadista, hirarka-soo-gaadhista ayaa sii yaraanaya ka dib marka isha iftiinka la qaato, iyo iftiinka ultraviolet ee ba'an ee mawjada 10 ilaa 14 nm ayaa loo soo bandhigay sida isha iftiinka. Dhererka mowjadda iftiinka ultraviolet ee aadka u gaaban aad buu u gaaban yahay, iyo habka muraayadda indhaha ee la isticmaali karo inta badan wuxuu ka kooban yahay muraayadaha filimaanta badan sida Mo/Si ama Mo/Be.

Waxaa ka mid ah, milicsiga ugu badnaan aragtiyeed ee filimka Mo/Si multilayer ee baaxadda mawjadda dhererka ee 13.0 ilaa 13.5nm waa qiyaastii 70%, iyo aragtida ugu badan ee milicsiga filimka Mo/Be ee mowjadda gaaban ee 11.1nm waa qiyaastii 80%. In kasta oo milicsiga muraayadaha filimka Mo/Be ee isku-dhafan ay sarreeyaan, Be aad ayuu u suntan yahay, sidaa darteed cilmi-baadhista agabka noocaas ah waa laga tagay markii la horumarinayo tignoolajiyada lithography EUV.Tiknoolajiyada lithography EUV ee hadda waxay isticmaashaa filimka Mo/Si multilayer, iyo hirarkeeda dhererka ayaa sidoo kale la go'aamiyay inuu noqdo 13.5nm.

Isha ilayska ultraviolet ee xad dhaafka ah ee caadiga ah waxay isticmaashaa tignoolajiyada balasmaha soo saarta laysarka (LPP), kaas oo adeegsada leysarka xooga sare si ay u kiciso kuleylka kulul ee Sn balaasmaha si ay u soo saarto iftiinka. Muddo dheer, awoodda iyo helitaanka isha iftiinka ayaa ahaa caqabadaha xaddidaya waxtarka mashiinnada lithography EUV. Iyada oo loo marayo cod-weyneeye awoodda oscillator-ka, tignoolajiyada balasmaha (PP) ee saadaalinta iyo tignoolajiyada nadiifinta muraayadda goobta, awoodda iyo xasilloonida ilaha iftiinka EUV ayaa si weyn loo hagaajiyay.

Mashiinka lithography ee EUV wuxuu inta badan ka kooban yahay nidaamyada hoose sida isha iftiinka, nalka, muraayadda ujeedada, marxaladda shaqada, marxaladda maaskaro, toosinta wafer, diiradda/saarista, gudbinta maaskaro, gudbinta maro, iyo fareeme vacuum. Ka dib marka la dhex maro nidaamka iftiiminta ee ka kooban muraayadaha lakabka badan, iftiinka ultraviolet ee xad-dhaafka ah ayaa lagu shideeyaa maaskarada milicsiga. Iftiinka ka muuqda maaskarada wuxuu galaa nidaamka sawir-qaadista guud ee muraayadda oo ka kooban taxane taxane ah, iyo ugu dambeyntii sawirka muuqda ee maaskarada ayaa lagu saadaaliyay dusha sare ee wafer ee jawi faaruq ah.

Goobta soo-gaadhista ee muuqaalka iyo sawirka sawirka ee mishiinka lithography ee EUV labaduba waa qaab-qaabaysan, iyo habka sawir-qaadista ee tallaabo-tallaabo ah ayaa loo isticmaalaa si loo gaaro soo-gaadhis buuxda si loo hagaajiyo heerka wax-soo-saarka. Mashiinka Lithography-ga ASML ee taxanaha NXE ee ugu horumarsan wuxuu isticmaalaa isha iftiinka oo leh mawjad dhererkeedu yahay 13.5nm, maaskaro ka tarjumaysa (6° dhacdo macquul ah) goobta iskaanka ee muuqaalka 26mm × 33mm, iyo bay'ad gaadhid faaruq ah.

Marka la barbar dhigo mishiinnada lithography immersion, xallinta hal-soo-saarka mashiinnada lithography ee EUV ee isticmaalaya ilaha iftiinka ultraviolet-ka ayaa si weyn loo hagaajiyay, taas oo si wax ku ool ah uga fogaan karta habka adag ee looga baahan yahay sawir-qaadista badan si loo sameeyo garaafyo heer sare ah. Waqtigan xaadirka ah, xallinta kaliya ee soo-gaadhista ee mashiinka lithography NXE 3400B oo leh dalool nambareed ah 0.33 wuxuu gaaraa 13nm, heerka wax-soo-saarkuna wuxuu gaarayaa 125 xabbo / saac.

Si loo daboolo baahiyaha kordhinta dheeraadka ah ee Sharciga Moore, mustaqbalka, mashiinnada lithography ee EUV oo leh aperture tirooyin ah 0.5 waxay qaadan doonaan nidaam ujeedo saadaal ah oo leh xannibaadda iftiinka dhexe, iyadoo la adeegsanayo weyneynta asymmetric ee 0.25 jeer/0.125 jeer, iyo 26m × 33mm waxaa laga dhimi doonaa 26mm × 16.5mm. ka hooseeya 8nm.

—————————————————————————————————————————————————————— ———————————

Semicera ayaa bixin karaqaybaha garaafka, jilicsan/dareen adag, qaybaha carbide silicon, CVD qaybaha carbide siliconiyoQaybaha dahaarka leh ee SiC/TaCoo leh habka semiconductor buuxa 30 maalmood gudahood.

Haddii aad xiisaynayso alaabta kor ku xusan,fadlan ha ka waaban inaad nala soo xidhiidho marka ugu horeysa.

Tel: +86-13373889683

WhatsAPP: +86-15957878134

Email: sales01@semi-cera.com

Waqtiga boostada: Agoosto-31-2024