Substrate-yada Silicon carbide (SiC) waxay leeyihiin cillado badan oo ka hortagaya socodsiinta tooska ah. Si loo abuuro wafers chips, filim gaar ah oo hal-crystal ah waa in lagu beeraa substrate-ka SiC iyada oo loo marayo habka epitaxial. Filimkan waxaa loo yaqaan lakabka epitaxial. Ku dhawaad dhammaan aaladaha SiC ayaa lagu xaqiiqsaday agabka epitaxial-ka, iyo agabka SiC-da ee-homoepitaxial oo tayo sare leh ayaa aasaas u ah horumarinta aaladda SiC. Waxqabadka qalabka epitaxial wuxuu si toos ah u go'aamiyaa waxqabadka qalabka SiC.

Aaladaha SiC ee hadda-sare iyo la isku halleyn karo waxay ku soo rogaan shuruudo adag qaab-dhismeedka dusha sare, cufnaanta cilladda, lebbiska doping, iyo lebbiska dhumucdaepitaxialagabka. Gaaritaanka cabbir weyn, cufnaanta cillad-hoose, iyo qaab-dhismeedka sare ee SiC epitaxy ayaa muhiim u ah horumarinta warshadaha SiC.

Soo saarista SiC epitaxy tayo sare leh waxay ku tiirsan tahay habab horumarsan iyo qalab. Hadda, habka ugu badan ee loo isticmaalo koritaanka SiC epitaxial waaKaydinta Uumiga Kiimikada (CVD).CVD waxay bixisaa xakameyn sax ah oo ku saabsan dhumucda filimka epitaxial iyo xoojinta doping, cufnaanta cilladaha hooseeya, heerka kobaca dhexdhexaadka ah, iyo xakamaynta habka otomaatiga ah, taasoo ka dhigaysa tignoolajiyada lagu kalsoonaan karo ee codsiyada ganacsiga guuleysta.

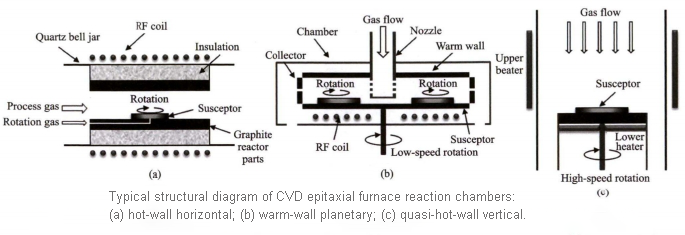

SiC CVD epitaxyguud ahaan waxay shaqaaleysiisaa qalabka CVD-da-kulul ama darbiga diirran. Heerkulka koritaanka sare (1500-1700 ° C) waxay hubisaa sii wadida qaabka crystalline 4H-SiC. Iyada oo ku saleysan xiriirka ka dhexeeya jihada socodka gaaska iyo dusha sare ee substrate, qolalka falcelinta ee nidaamyadan CVD waxaa loo kala saari karaa qaab-dhismeedyo toosan iyo kuwo toosan.

Tayada foornooyinka epitaxial ee SiC waxaa inta badan lagu qiimeeyaa seddex dhinac: waxqabadka kobaca epitaxial (oo ay ku jiraan lebbiska dhumucda, lebiska doping, heerka cilladda, iyo heerka korriinka), waxqabadka heerkulka qalabka (oo ay ku jiraan heerkulka kuleylka / qaboojinta, heerkulka ugu sarreeya, iyo lebbiska heerkulka ), iyo wax-ku-oolnimada (oo ay ku jiraan qiimaha halbeegga iyo awoodda wax-soo-saarka).

Farqiga u dhexeeya Saddexda Nooc ee Foornooyinka Kobaca Epitaxial SiC

1.Darbiga Horizontal CVD Systems:

-Astaamaha:Guud ahaan waxay muujisaa nidaamyada kobaca cabbirka weyn ee hal-wafer-ka ah ee uu hoggaamiyo wareegga sabaynta gaaska, gaarista cabbirrada wafer-ka-dhexdhexaadka ah ee aad u wanaagsan.

-qaabka wakiil:LPE's Pe1O6, oo awood u leh raritaan/dejinta wafer otomaatig ah at 900°C. Loo yaqaan heerarka kobaca sare, wareegyada epitaxial gaagaaban, iyo wafer-wafer joogto ah iyo waxqabadka dhexmara.

-Waxqabadka:Wixii 4-6 inch 4H-SiC wafers epitaxial oo leh dhumucdiisuna tahay ≤30μm, waxay gaartaa dhumucdiisuna tahay intra-wafer-la-midaysan bedka dhulka (unugyada 2mm × 2mm) ≥90%.

-Warshadaha gudahaShirkadaha sida Jingsheng Mechatronics, CETC 48, North Huachuang, iyo Nasset Intelligent waxay soo saareen qalab isku mid ah oo SiC epitaxial ah oo la mid ah.

2. Nidaamyada CVD Planetary Planetary:

-Astaamaha:U isticmaal saldhigyada habaynta meeraha korriinka wafer-ka badan ee dufcaddiiba, taasoo si weyn u horumarinaysa wax-soo-saarka.

-Qaababka Matalayaasha:Aixtron's AIXG5WWC (8x150mm) iyo G10-SiC (9x150mm ama 6x200mm).

-Waxqabadka:Wixii 6-inch 4H-SiC wafers epitaxial oo leh dhumucdiisuna tahay ≤10μm, waxay ku guulaysataa leexashada dhumucda inter-wafer ± 2.5%, dhumucda intra-wafer ee aan la mid ahayn 2%, isugeynta doping inter-wafer ± 5%, iyo doping intra-wafer fiirsashada oo aan la mid ahayn <2%.

-Caqabadaha:Korsashada xaddidan ee suuqyada gudaha sababtoo ah la'aanta xogta wax-soo-saarka dufcadaha, caqabadaha farsamada ee heerkulka iyo xakamaynta goobta socodka, iyo R&D socda iyada oo aan la hirgelin ballaaran.

3. Nidaamyada CVD-ga-kulul-kulul-ku-kulul:

- Tilmaamaha:Ka faa'iidayso gargaarka farsamada dibadda ee wareegga xawaaraha sare ee substrate, yaraynta dhumucda lakabka xadka iyo hagaajinta heerka kobaca epitaxial, oo leh faa'iidooyin dabiici ah oo ku jira xakamaynta cilladda.

- Qaababka Matalayaasha:Nuflare's hal-wafer EPIREVOS6 iyo EPIREVOS8.

-Waxqabadka:Wuxuu gaaraa heerarka kobaca ee ka badan 50μm/saacadii, kontoroolka cufnaanta cilada dusha ee ka hooseeya 0.1 cm-², iyo dhumucda wafer-ka iyo fiirsashada aan la mid ahayn 1% iyo 2.6%, siday u kala horreeyaan.

-Horumarinta Guriga:Shirkadaha sida Xingsandai iyo Jingsheng Mechatronics waxay naqshadeeyeen qalab la mid ah laakiin ma aysan gaarin isticmaalka ballaaran.

Soo koobid

Mid kasta oo ka mid ah saddexda nooc ee qaab dhismeedka qalabka kobaca Epitaxial SiC wuxuu leeyahay sifooyin kala duwan wuxuuna haystaa qaybo gaar ah oo suuqa ah oo ku saleysan shuruudaha dalabka. CVD-ga tooska ah ee gidaarka kulul waxa uu bixiyaa heerarka kobaca aadka u degdega ah iyo tayada isku dheeli tiran iyo lebiska laakiin waxa ay leedahay wax soo saar hoose oo ay ugu wacan tahay farsamaynta hal-wafer. CVD meeraha diirran ee diirran ayaa si weyn u wanaajiya waxtarka wax soo saarka laakiin waxa uu wajahayaa caqabado ku jira xakamaynta joogteynta wafer-badan. Quasi-hot-wall CVD toosan ayaa aad uga sarreeya xakamaynta cilladda leh qaab dhismeed adag waxayna u baahan tahay dayactir ballaaran iyo khibrad hawleed.

Marka ay warshaduhu horumaraan, kobcinta soo noqnoqota iyo cusboonaysiinta qaab-dhismeedka qalabkan ayaa u horseedi doona qaabayn la safeeyey oo sii kordheysa, iyada oo doorar muhiim ah ka ciyaaraysa buuxinta qeexitaannada waferka epitaxial ee kala duwan ee shuruudaha dhumucda iyo cilladaha.

Faa'iidooyinka iyo khasaarooyinka Foornooyinka Kobaca Epitaxial SiC ee kala duwan

| Nooca Foornada | Faa'iidooyinka | Khasaaro | Soo-saareyaal matale |

| Derbiga-kulul Horizontal CVD | Heerka kobaca degdega ah, qaab dhismeedka fudud, dayactirka fudud | Wareegga dayactirka gaaban | LPE (Talyaani), TEL (Japan) |

| Planetary CVD ee gidaarka diiran | Awood wax soo saar sare, hufan | Qaab dhismeedka adag, xakamaynta joogtada ah ee adag | Aixtron (Jarmalka) |

| Quasi-kulul-derbi toosan CVD | Xakamaynta cillad aad u fiican, wareegga dayactirka dheer | Qaab dhismeed adag, oo ay adagtahay in la ilaaliyo | Nuflare (Japan) |

Horumarinta warshadaha ee joogtada ah, saddexdan nooc ee qalabku waxay mari doonaan hagaajinta qaabdhismeedka iyo hagaajinta, taasoo horseedaysa qaabaynta sii kordheysa ee la safeeyey ee ku habboon noocyada kala duwan ee waferka epitaxial ee dhumucda iyo shuruudaha cilladda.

Waqtiga boostada: Jul-19-2024