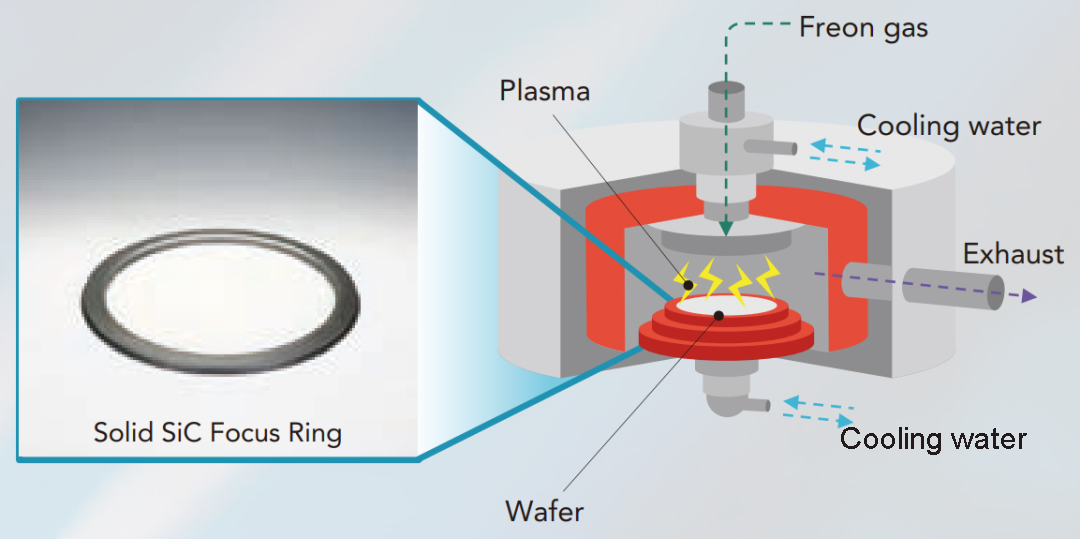

Qalabka etching plasma, qaybaha dhoobada ayaa door muhiim ah ka ciyaara, oo ay ku jiraangiraanta diiradda.The giraanta diiradda, oo la dhigo hareeraha maraqa iyo xiriir toos ah oo lala yeesho, ayaa lagama maarmaan u ah diiradda saarista balasmaha ee waferka iyadoo la gelinayo korantada giraanta. Tani waxay kor u qaadaysaa isku mid ahaanshaha habka xoqidda.

Codsiga SiC Focus Rings ee Mashiinnada Etching

Qaybaha SiC CVDMashiinnada etching, sidagiraanta diiradda, madaxyada qubeyska gaaska, platens, iyo giraanta cidhifyada, ayaa la jecel yahay sababtoo ah falcelinta hoose ee SiC ee leh chlorine iyo fluorine-ku salaysan gaaska etching iyo conductivity, taasoo ka dhigaysa wax ku habboon qalabka etching plasma.

Faa'iidooyinka SiC sida Qalabka Giraanta Diirada-saar

Sababo la xiriira soo-gaadhista tooska ah ee balasmaha ee qolka falcelinta faakuumka, giraanta diirada ayaa loo baahan yahay in laga sameeyo walxaha u adkaysta balaasmaha. Faraanti diiradda dhaqameed, oo laga sameeyay silikoon ama quartz, waxay la ildaran yihiin iska caabbinta etching liidata ee balaasmooyinka fluorine-ku-salaysan, taasoo horseedaysa daxalka degdega ah iyo hoos u dhaca waxtarka.

Isbarbardhigga u dhexeeya Si iyo CVD SiC Focus Rings:

1. Cufnaanta Sare:Waxay yaraynaysaa mugga xoqidda.

2. Bannaanka ballaaran: Waxay bixisaa dahaarka aad u fiican.

3. Dhaqdhaqaaqa Kulaylka Sareeya & Iskuxidhka Balaadhinta Hoose: U adkaysta shoogga kulaylka.

4. Balaasti sareIska caabbinta wanaagsan ee saameynta farsamada.

5. Adag Adag: Xiro iyo daxalka u adkaysta.

SiC waxay la wadaagtaa dhaqdhaqaaqa korantada ee silikoon iyadoo bixinaysa iska caabin heersare ah oo ku wajahan ionic etching. Maaddaama yaraynta wareegga isku dhafan ee isku dhafan ay sii socoto, baahida loo qabo hababka etching ee waxtarka leh ayaa kordha. Qalabka Plasma etching, gaar ahaan kuwa isticmaalaya balaasmaha capacitive-ka ah (CCP), waxay u baahan yihiin tamar balaasmaha sare leh, samayntaSiC diiradda giraantacaan sii kordheysa.

Si iyo CVD SiC Focus Reing Parameters:

| Halbeegga | Silikoon (Si) | CVD Silicon Carbide (SiC) |

| Cufnaanta (g/cm³) | 2.33 | 3.21 |

| Farqiga Band (eV) | 1.12 | 2.3 |

| Dhaqdhaqaaqa Kulaylka (W/cm°C) | 1.5 | 5 |

| Isku xidhka Balaadhinta kulaylka (x10⁻⁶/°C) | 2.6 | 4 |

| Qalabka Elastic (GPa) | 150 | 440 |

| Adag | Hoose | Sareeye |

Habka wax-soo-saarka ee SiC Focus Rings

Qalabka semiconductor, CVD (Chemical Vapor Deposition) ayaa caadi ahaan loo isticmaalaa si loo soo saaro qaybaha SiC. Giraanta diirada waxaa lagu soo saaraa iyadoo lagu shubayo SiC qaabab gaar ah iyada oo loo marayo kaydinta uumiga, oo ay ku xigto farsamaynta farsamada si loo sameeyo badeecada ugu dambeysa. Saamiga walxaha ee kaydinta uumiga waa mid go'an ka dib tijaabo badan, samaynta cabbirro sida iska caabin joogto ah. Si kastaba ha ahaatee, qalabka etching kala duwan ayaa laga yaabaa in ay u baahan yihiin giraanno diiradda oo leh iska caabin kala duwan, oo lama huraan ah tijaabooyin saamiga walxaha cusub ee qeexitaan kasta, kaas oo waqti-qaadanaya oo qaali ah.

Adigoo dooranayaSiC diiradda giraantakaSemiconductor Semicera, macaamiishu waxay gaari karaan faa'iidooyinka wareegyada beddelka dheer iyo waxqabadka sare iyada oo aan la kordhin qiimaha la taaban karo.

Waxyaalaha ka-habaynta kulaylka degdega ah (RTP)

Guryaha kulaylka gaarka ah ee CVD SiC ayaa ka dhigaya mid ku habboon codsiyada RTP. Qaybaha RTP, oo ay ku jiraan giraanta cidhifka ah iyo taarikada, waxay ka faa'iidaystaan CVD SiC. Inta lagu jiro RTP, garaaca garaaca kulaylka daran ayaa lagu dabaqaa maraqyada gaarka ah muddo gaaban, oo ay ku xigto qaboojin degdeg ah. CVD SiC faraanti cidhifeedka, iyagoo dhuuban oo leh cuf kuleyl hooseeya, ma hayaan kulayl weyn, taasoo ka dhigaysa inaysan saameyn ku yeelan hababka kuleylka iyo qaboojinta degdega ah.

Qaybaha Etching Plasma

Caabbinta kiimikada sare ee CVD SiC ayaa ka dhigaysa mid ku habboon codsiyada xoqin. Qolal badan oo etching ah ayaa isticmaala taarikada qaybinta gaaska CVD SiC si ay u qaybiyaan gaaska etching, oo ka kooban kumanaan godad yar yar oo loogu talagalay firdiyaha balaasmaha. Marka la barbar dhigo agabka kale, CVD SiC waxay leedahay falcelin hoose oo leh koloriin iyo gaasaska fluorine. Marka ay engegto qallayl, qaybaha CVD SiC sida giraanta diiradda, ICP platens, giraanta xadka, iyo madaxyada qubeyska ayaa caadi ahaan loo isticmaalaa.

giraanta diirada SiC, oo leh danabkooda la dabaqay ee diirada saaraya balasmaha, waa inay lahaadaan korriin ku filan. Caadi ahaan ka samaysan silikoon, giraangiraha diirada ayaa la kulmaya gaasas fal-celin ah oo ay ku jiraan fluorine iyo koloriin, taasoo keenta daxalka lama huraanka ah. Giraanta diirada SiC, oo leh iska caabin daxalka sare leh, waxay bixiyaan cimri dheer marka loo eego silikoon faraanti ah.

Isbarbardhigga Wareegga Nolosha:

SiC Focus ringings:La beddelo 15 ilaa 20 maalmood kasta.

Silikoon Diirada Saaran:La beddelo 10 ilaa 12 maalmood kasta.

In kasta oo giraangiraha SiC ay 2 ilaa 3 jeer ka qaalisan yihiin silikoon, wareegga beddelka ee dheeraadka ah wuxuu yareynayaa kharashyada beddelka qaybaha guud, maadaama dhammaan qaybaha xidhashada qolka lagu beddelayo isla mar marka qolka la furo beddelka giraanta diiradda.

Semicera Semiconductor's SiC Focus Rings

Semicera Semiconductor wuxuu bixiyaa giraanta diirada SiC qiimo u dhow kuwa giraannada silikoon, oo leh waqti ledh ku dhawaad 30 maalmood ah. Marka la isku daro Semicera's SiC giraanta foojignaanta qalabka plasma etching, hufnaanta iyo cimri dhererka ayaa si weyn loo wanaajiyey, hoos u dhigista kharashka dayactirka guud iyo kor u qaadista waxtarka wax soo saarka. Intaa waxaa dheer, Semicera waxay habeyn kartaa iska caabinta giraanta diiradda si ay u buuxiso shuruudaha macaamiisha gaarka ah.

Iyagoo dooranaya giraanta diirada SiC ee Semicera Semiconductor, macaamiishu waxay gaari karaan faa'iidooyinka wareegyada beddelka dheer iyo waxqabadka sare iyada oo aan la kordhin qiimaha la taaban karo.

Waqtiga boostada: Jul-10-2024