Qalabka korantada ee Semiconductor waxay ku jiraan booska aasaasiga ah ee nidaamyada korantada korantada, gaar ahaan marka la eego horumarka degdega ah ee tignoolajiyada sida sirdoonka macmal, isgaarsiinta 5G iyo baabuurta tamarta cusub, shuruudaha waxqabadka iyaga ayaa la hagaajiyay.

Silikoon carbide(4H-SiC) waxay noqotay wax ku habboon soo saarista aaladaha korantada semiconductor-ka sare leh sababtoo ah faa'iidooyinkeeda sida bandgap ballaaran, kuleylka kuleylka sare, xoogga sare ee burburka, heerka qulqulka sare ee qulqulka, xasilloonida kiimikada iyo iska caabbinta shucaaca. Si kastaba ha ahaatee, 4H-SiC waxay leedahay engegnaan sare, jajabnaan sare, firfircoonaan la'aan kiimiko oo xoog leh, iyo dhib habayn heersare ah. Tayada dusha sare ee waferka substrate-ka ayaa muhiim u ah codsiyada aaladaha waaweyn.

Sidaa darteed, hagaajinta tayada dusha sare ee 4H-SiC wafers substrate, gaar ahaan ka saarida lakabka dhaawacan ee dusha sare ee farsamaynta wafer, waa furaha lagu gaaro wax ku ool ah, khasaaro hoose iyo tayo sare leh 4H-SiC substrate wafer.

Tijaabi

Tijaabadu waxay isticmaashaa 4-inji N-nooca 4H-SiC ingot oo lagu koray habka gaadiidka uumiga jirka, kaas oo lagu farsameeyo goynta siliga, shiididda, shiididda qallafsan, shiididda iyo turxaan bixinta, waxayna diiwaan gelisaa dhumucda ka saarida dusha C iyo dusha Si iyo dhumucda malab ee ugu dambeeya ee geedi socod kasta.

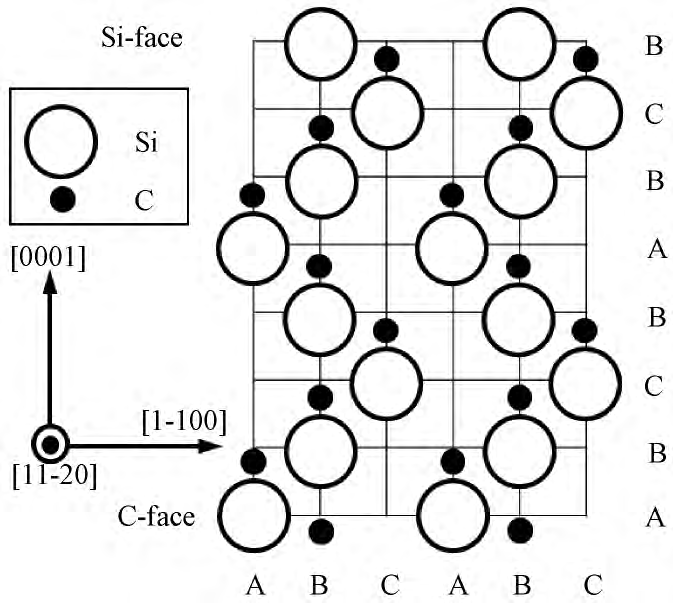

Jaantuska 1 jaantuska qaabdhismeedka 4H-SiC crystal

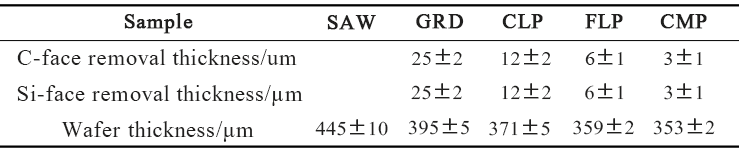

Jaantuska 2 Dhumucda laga saaray C-side iyo Si-side ee 4H-SiC waferka dib markii tallaabooyin processing kala duwan iyo dhumucdiisuna waxay of wafer ka dib markii processing

Dhumucda, qaab-dhismeedka dusha sare, qallafsanaanta iyo sifooyinka farsamaysan ee waferka ayaa si buuxda loogu asteeyay tijaabiyaha cabbiraadda joomatariga wafer, mikroskoob kala duwan oo faragelin ah, mikroskoob xoogga atomiga, qalabka cabbira qallafsanaanta iyo nanoindenter. Intaa waxaa dheer, diffractometer X-ray-xalinta sare ah ayaa loo isticmaalay si loo qiimeeyo tayada kareemka ee waferka.

Talaabooyinkan tijaabada ah iyo hababka imtixaanku waxay bixiyaan taageero farsamo oo faahfaahsan oo lagu baranayo heerka ka saarista walxaha iyo tayada dusha sare inta lagu jiro habaynta 4H-SiC wafers.

Tijaabooyin, cilmi-baarayaashu waxay falanqeeyeen isbeddelada heerka saarista walxaha (MRR), qaab-dhismeedka dusha sare iyo qallafsanaanta, iyo sidoo kale qalabka farsamada iyo tayada crystal ee 4H-SiC wafersTallaabooyin habaysan oo kala duwan (goynta silig, shiidid, shiidid qallafsan, shiidid fiican, polishing).

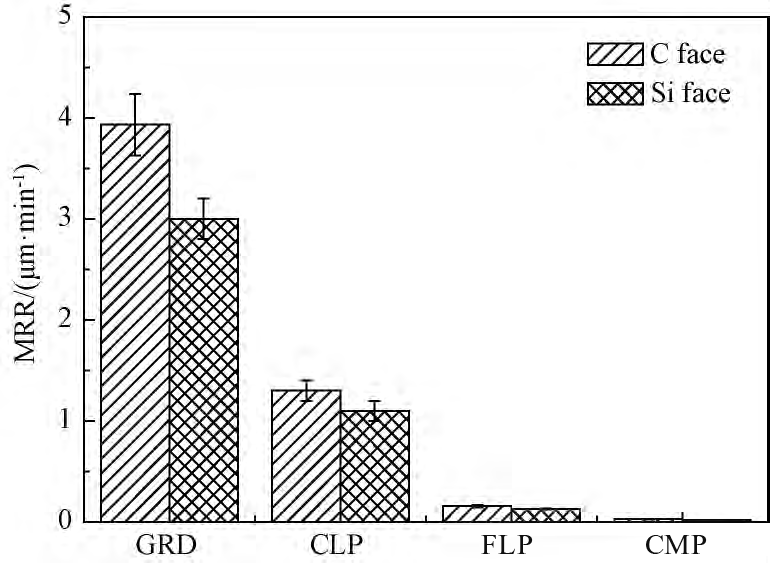

Jaantuska 3 Heerka saarista walxaha ee wajiga C-wejiga iyo wejiga 4H-SiC wafertalaabooyinka habaynta ee kala duwan

Daraasadu waxay ogaatay in ay sabab u tahay anisotropy ee sifooyinka farsamada ee wajiyada crystal ee kala duwan ee 4H-SiC, waxaa jira farqi u dhexeeya MRR u dhexeeya C-wejiga iyo Si-wejiga hoos habka isku mid ah, iyo MRR ee C-wejiga ayaa aad uga sarreeya marka loo eego. kan Si-face. Iyadoo horumarinta tillaabooyinka habaynta, qaab-dhismeedka dusha sare iyo qallafsanaanta 4H-SiC wafers ayaa si tartiib tartiib ah loo hagaajiyaa. Ka dib dhalaalidda, Ra ee C-wejiga waa 0.24nm, iyo Ra ee Si-face wuxuu gaaraa 0.14nm, kaas oo dabooli kara baahida koritaanka epitaxial.

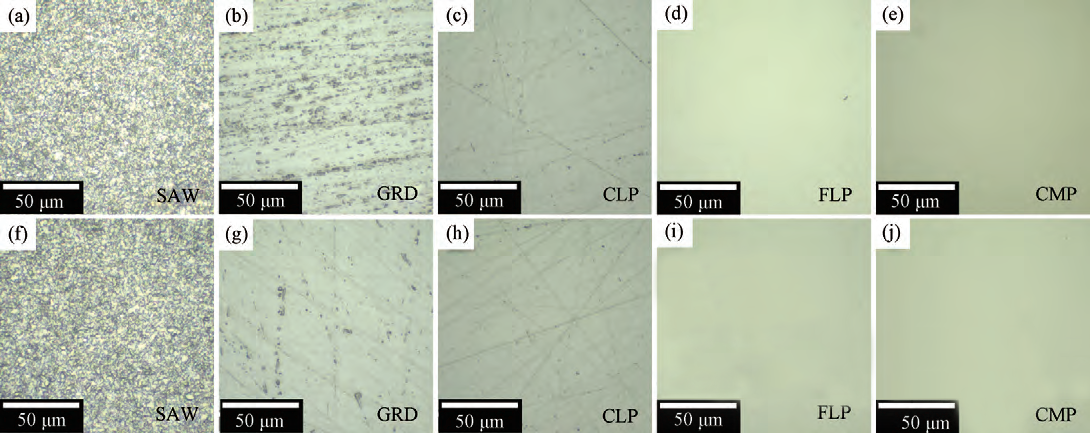

Jaantuska 4 Sawirada mikroskoob ee indhaha ee dusha C (a ~ e) iyo Si dusha sare (f~j) ee wafer 4H-SiC ka dib tilaabooyin habaysan oo kala duwan

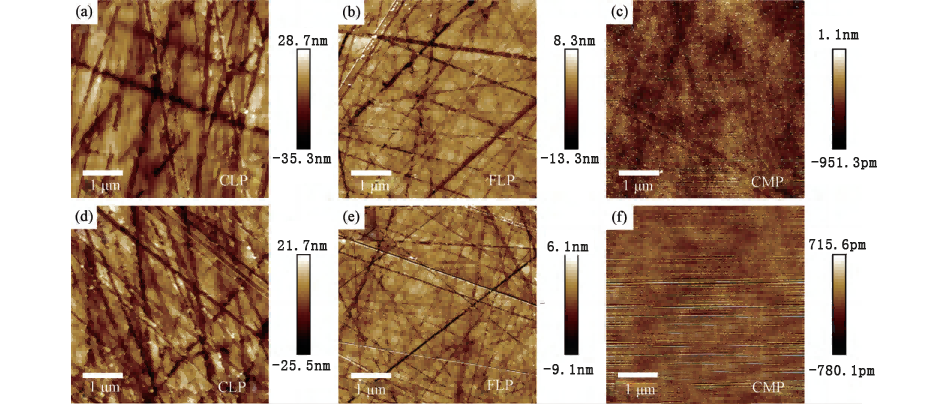

Jaantuska 5 Sawirada mikroskoob ee xoogga atomiiga ee dusha C (a ~ c) iyo Si dusha sare (d ~ f) ee wafer 4H-SiC ka dib CLP, FLP iyo CMP

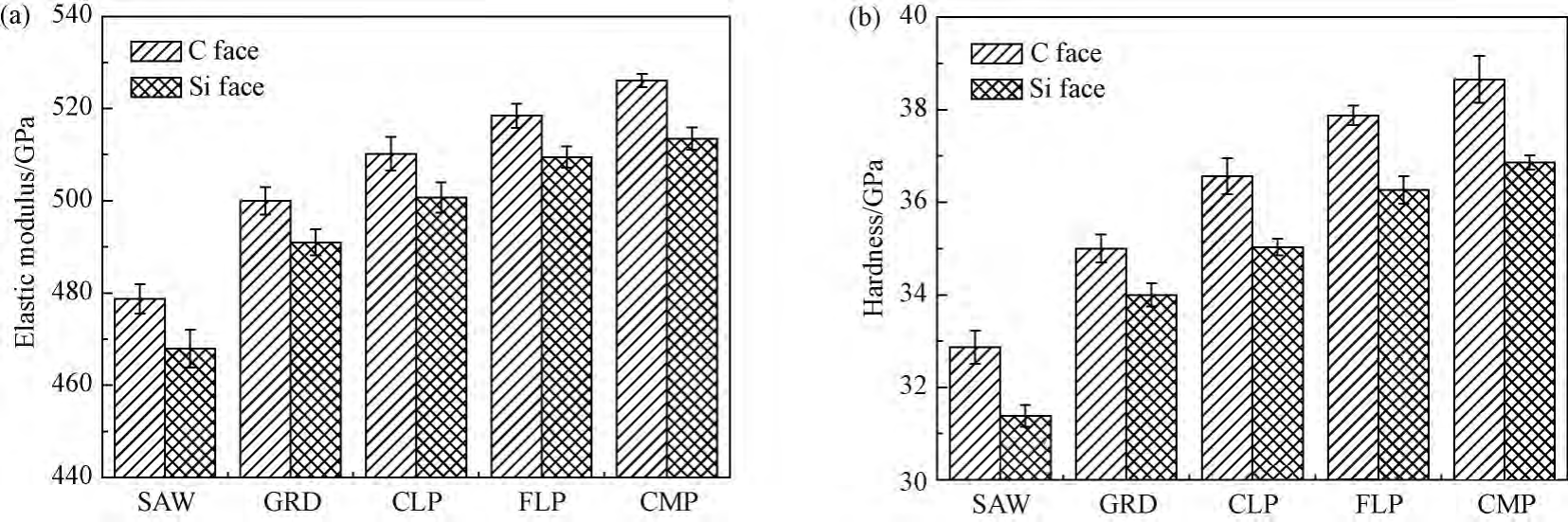

Jaantuska 6 (a) modules laastikada iyo (b) engegnaanta dusha C iyo Si dusha sare ee 4H-SiC wafer kadib tillaabooyin habaysan oo kala duwan

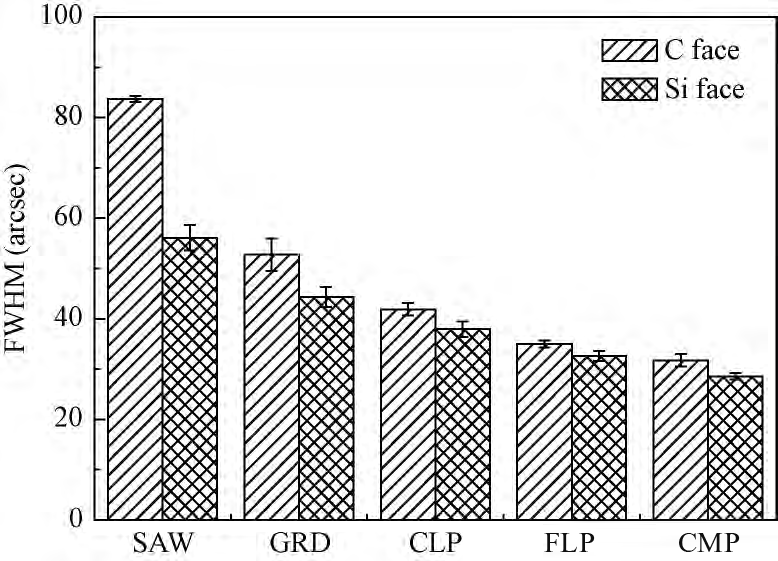

Tijaabada hantida makaanikku waxay muujinaysaa in dusha C ee waferku uu ka adag yahay kan Si dusha sare, heer aad u weyn oo jab jaban inta lagu jiro farsamaynta, ka saarista alaabta, iyo qaab-dhismeedka dusha sare oo liita iyo qallafsanaan. Ka saarida lakabka dhaawacan ee dusha la warshadeeyay ayaa fure u ah hagaajinta tayada dusha sare ee waferka. Ballaca dhererka nuska ah ee 4H-SiC (0004) qalooca ruxaya waxa loo isticmaali karaa si dareen leh oo sax ah loo garto oo loo falanqeeyo lakabka waxyeelada dusha sare ee maraqa.

Jaantus 7 (0004) qalooca qalooca nus ballaca C-wejiga iyo wejiga 4H-SiC ee waferka kadib tilaabooyin habaysan oo kala duwan

Natiijooyinka cilmi-baaristu waxay muujinayaan in lakabka dhaawaca dusha sare ee wafer si tartiib tartiib ah loo saari karo ka dib markii 4H-SiC farsamaynta wafer, taas oo si wax ku ool ah u wanaajisa tayada dusha sare ee wafer waxayna bixisaa tixraac farsamo oo tayo sare leh, khasaare hoose iyo tayo sare leh. ee 4H-SiC wafers substrate.

Cilmi-baadhayaashu waxay farsameeyeen maraqa 4H-SiC iyada oo loo marayo tillaabooyin habaysan oo kala duwan sida goynta siliga, shiididda, shiididda qallafsan, shiididda ganaaxa iyo nadiifinta, waxayna daraasad ku sameeyeen saamaynta hababkan tayada dusha sare ee maraqa.

Natiijooyinku waxay muujinayaan in horumarinta tillaabooyinka habaynta, qaab-dhismeedka dusha sare iyo qallafsanaanta wafer si tartiib tartiib ah loo hagaajiyo. Ka dib markii la nadiifiyo, qallafsanaanta C-face iyo Si-face waxay gaartaa 0.24nm iyo 0.14nm siday u kala horreeyaan, taas oo buuxisa shuruudaha koritaanka epitaxial. Wejiga C-ga wafer-ku wuu ka adag yahay shayga Si-face, wuxuuna aad ugu nugul yahay jabka dillaaca inta lagu jiro habaynta, taasoo keenta qaab-dhismeedka dusha sare oo liita iyo qallafsanaan. Ka saarida lakabka waxyeellada dusha sare ee dusha la warshadeeyay ayaa fure u ah hagaajinta tayada dusha sare ee waferka. Balaadhka kala badh ee 4H-SiC (0004) qalooca ruxaya ayaa si dareen leh oo sax ah u tilmaami kara lakabka waxyeellada dusha sare ee maraqa.

Cilmi-baaristu waxay muujinaysaa in lakabka dhaawacan ee dusha sare ee 4H-SiC wafers si tartiib tartiib ah looga saari karo iyada oo loo marayo farsamaynta 4H-SiC, si wax ku ool ah u wanaajinta tayada dusha sare ee wafer-ka, bixinta tixraac farsamo ee waxtarka sare, luminta hoose, iyo sare- habaynta tayada wafers substrate 4H-SiC.

Waqtiga boostada: Jul-08-2024