Silikon carbide (SiC) epitaxy

Saxanka epitaxial, kaas oo haya substrate-ka SiC si uu u kobciyo jeexjeexa SiC epitaxial, oo la dhex dhigo qolka falcelinta oo si toos ah ula xidhiidha waferka.

Qaybta sare ee dayaxa-moonku waa sidayaal qalabyo kale oo ka mid ah qolka falcelinta ee qalabka Sic epitaxy, halka qaybta hoose ee nus-moon ay ku xiran tahay tuubada quartz, oo soo bandhigaysa gaaska si loo kaxeeyo saldhigga susceptor si uu u wareego. waa kuwo heerkul-ku-koontarool ah oo lagu rakibay qolka falcelinta iyada oo aan si toos ah loola xiriirin waferka.

Sida epitaxy

Saxanka, kaas oo haya substrate-ka Si loogu beero jeexjeexa Si epitaxial, oo la dhex dhigo qolka falcelinta oo si toos ah ula xidhiidha maraqa.

Giraanta kuleylka hore waxay ku taal giraanta dibadda ee Si epitaxial substrate tray waxaana loo isticmaalaa hagaajinta iyo kuleylinta. Waxa la dhigayaa qolka falcelinta oo si toos ah ulama xidhiidhin waferka.

Susceptor epitaxial, kaas oo sita substrate-ka Si loogu beero jeex Epitaxial Si, oo la dhex dhigo qolka falcelinta oo si toos ah ula xidhiidha waferka.

Foosto Epitaxial waa qaybaha muhiimka ah ee loo isticmaalo hababka wax soo saarka semiconductor ee kala duwan, guud ahaan loo isticmaalo qalabka MOCVD, oo leh xasilooni kulayl aad u fiican, caabbinta kiimikada iyo xirashada caabbinta, aad ugu habboon isticmaalka hababka heerkulka sare. Waxay la xiriirtaa waferrada.

| Astaamaha jireed ee Silicon Carbide dib loo soo celiyay | |

| Hanti | Qiimaha caadiga ah |

| Heerkulka shaqada (°C) | 1600°C (oo oksijiin leh), 1700°C (hoos u dhaca deegaanka) |

| Nuxurka SiC | > 99.96% |

| Ka kooban Si bilaash ah | <0.1% |

| Cufnaanta weyn | 2.60-2.70 g/cm3 |

| Borosity muuqda | <16% |

| Xoog cadaadis | > 600 MPa |

| Xoog laabashada qabow | 80-90 MPa (20°C) |

| Xoog foorarsi kulul | 90-100 MPa (1400°C) |

| Balaadhinta kulaylka @1500°C | 4.70 10-6/°C |

| Dhaqdhaqaaqa kulaylka @1200°C | 23 W/m•K |

| modules laastikada | 240 GPA |

| Iska caabbinta shoogga kulaylka | Aad u wanaagsan |

| Astaamaha jireed ee Sintered Silicon Carbide | |

| Hanti | Qiimaha caadiga ah |

| Halabuurka Kiimikada | SiC>95%, Si<5% |

| Cufnaanta Bulk | >3.07 g/cm³ |

| Borosity muuqda | <0.1% |

| Hababka dillaaca ee 20 ℃ | 270 MPa |

| Hababka dillaaca ee 1200 ℃ | 290 MPa |

| Adag markay tahay 20 ℃ | 2400 Kg/mm² |

| adkaanta jabka 20% | 3.3 MPa · m1/2 |

| Heerarka kulaylka ee 1200 ℃ | 45 w/m .K |

| Balaadhinta kulaylka at 20-1200 ℃ | 4.5 1 ×10 -6/℃ |

| Heerkulka shaqada ugu badan | 1400 ℃ |

| U adkaysiga shoogga kulaylka at 1200 ℃ | Wacan |

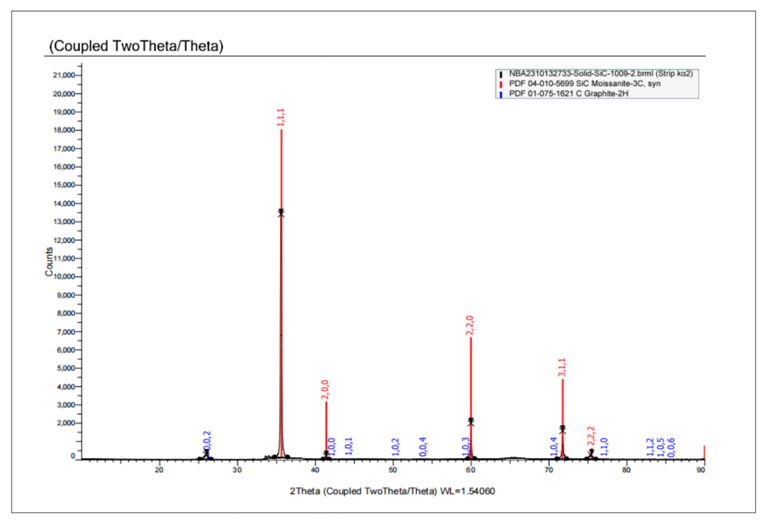

| Astaamaha asaasiga ah ee filimada CVD SiC | |

| Hanti | Qiimaha caadiga ah |

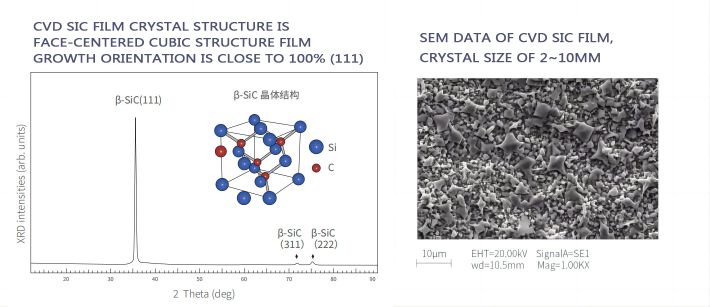

| Dhismaha Crystal | FCC β wajiga polycrystalline, inta badan (111) ku jihaysan |

| Cufnaanta | 3.21 g/cm³ |

| Adag 2500 | (500g oo rar ah) |

| Cabirka Hadhuudhka | 2 ~ 10μm |

| Nadiifnimada Kiimikada | 99.99995% |

| Awoodda kulaylka | 640 · kg-1·K-1 |

| Heerkulka Sublimation | 2700 ℃ |

| Xoog Jilicsan | 415 MPa RT 4-dhibic |

| Modulka dhalinyarada | 430 Gpa 4pt laab, 1300 ℃ |

| Habdhaqanka kulaylka | 300W·m-1·K-1 |

| Balaadhinta kulaylka (CTE) | 4.5×10-6 K -1 |

Tilmaamaha ugu muhiimsan

Dusha sare waa cufan oo aan lahayn daloolno.

Nadiifin sare, wadarta guud ee wasakhda <20ppm, hawo-mareen wanaagsan.

Iska caabin heerkul sarreeya, xooggu wuxuu kordhiyaa heerkulka isticmaalka oo sii kordhaya, isagoo gaaraya qiimaha ugu sarreeya ee 2750 ℃, hoos u dhigista 3600 ℃.

modules laastikada hoose, conductivity kaamerada sare, coefficient fidinta kulaylka hoose, iyo caabbinta shoogga kulaylka aad u fiican.

Degganaanshiyo kiimikaad oo wanaagsan, adkaysi u leh aashitada, alkali, cusbada, iyo reagents organic, oo aan wax saamayn ah ku yeelan biraha dhalaalay, dharbaaxada, iyo warbaahinta kale ee daxalaysa. Si aad ah uma oksijiyeen jawiga ka hooseeya 400 C, heerka oksaydhiskuna aad buu u kordho 800 ℃.

Adigoon wax gaas ah ku sii deyn heerkul sare, waxay ilaalin kartaa faakuumka 10-7mmHg qiyaastii 1800°C.

Codsiga alaabta

Ku dhalaalidda uumiga ee warshadaha semiconductor.

Albaabka tuubada elegtarooniga ah ee awooda sare leh.

caday oo la xidhiidha maamulaha danabka.

graphite monochromator ee raajada iyo neutron.

Qaabab kala duwan oo ah substrates graphite iyo daahan tuubada nuugista atomiga.

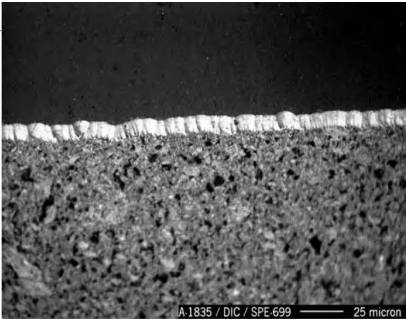

Saamaynta dahaarka kaarboonka ee pyrolytic ee hoos imanaya mikroskoob 500X ah, oo leh dusha aan qummanayn oo xidhan.

Dahaarka TaC waa jiilka cusub ee u adkaysta heerkulka sare, oo leh xasillooni heerkul sare oo ka wanaagsan SiC. Sida daahan daxalka u adkaysta, daahan anti-oxidation iyo daahan xidho u adkaysta, waxaa loo isticmaali karaa in deegaanka kor ku xusan 2000C, si ballaaran loo isticmaalo aerospace ultra-sare heerkulka sare qaybaha dhamaadka kulul, jiilka saddexaad semiconductor beeraha koritaanka crystal hal.

| Tilmaamaha jireed ee daahan TaC | |

| Cufnaanta | 14.3 (g/cm3) |

| Dheecaan gaar ah | 0.3 |

| Isku xidhka balaadhinta kulaylka | 6.3 10/K |

| Adag (HK) | 2000 HK |

| iska caabin | 1x10-5 Ohm*cm |

| Deganaanshaha kulaylka | <2500℃ |

| Cabbirka garaafiga ayaa isbeddela | -10 ~ -20um |

| Dhumucda dahaarka | ≥220um qiimaha caadiga ah (35um± 10um) |

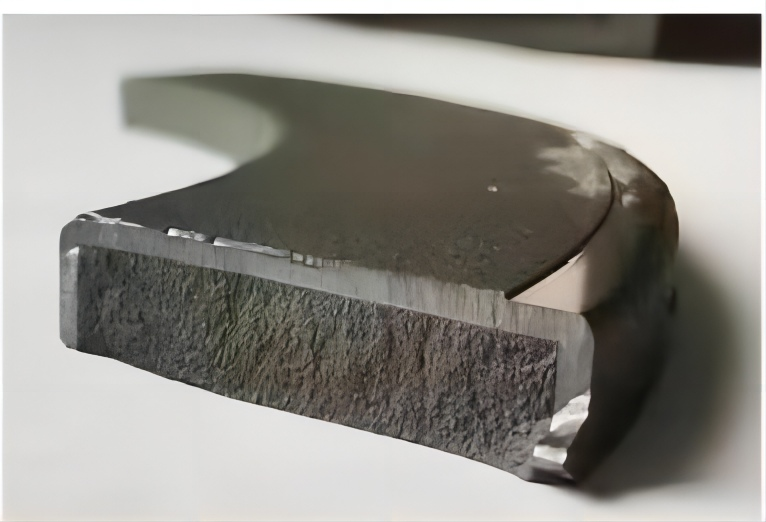

Qaybaha CVD SILICON CARBIDE ee adag waxaa loo aqoonsan yahay inay yihiin doorashada koowaad ee RTP/EPI giraanta iyo saldhigyada iyo qaybaha godka balasmaha ee ku shaqeeya nidaamka sare ee loo baahan yahay heerkulka hawlgalka (> 1500 ° C), shuruudaha nadiifinta ayaa si gaar ah u sarreeya (> 99.9995%) iyo waxqabadka ayaa si gaar ah u wanaagsan marka kiimikooyinka caabbinta tol ay si gaar ah u sarreeyaan. Qalabkani kuma jiraan wejiyada labaad ee cidhifka hadhuudhka, sidaa awgeed qaybaha ay ka kooban yihiin waxay soo saaraan qaybo ka yar alaabta kale. Intaa waxaa dheer, qaybahan waxaa lagu nadiifin karaa iyadoo la isticmaalayo HF/HCI kulul oo leh hoos u dhac yar, taasoo keeneysa qaybo yar iyo nolol adeeg oo dheer.