Garaafka silikoonized waa walxo isku dhafan oo silikoon carbide ku xiran tahay dusha sare ee garaafyada. Waxay leedahay sifooyinka qallafsanaanta sare, xoogga farsamada sare iyo xirashada caabbinta silikoon carbide, iyo sidoo kale sifooyinka is-saliimaynta iyo caabbinta shoogga kuleylka ee graphite. Waa qalab isku-dhafan oo ku habboon iyo qalabka shaabadda makaanikada, oo ku habboon xiridda makaanikada ee matoorada biyaha ee kala duwan, bambooyinka saliidda, bambooyin kiimikaad, iyo xajiyeyaasha kala duwan ee xawaaraha sare iyo kuwa xamuulka ah ee bambooyin waaweyn oo kala duwan. Intaa waxaa dheer, graphite siliconized waxay leedahay iska caabin oksaydh oo wanaagsan, iska caabin shoog kulaylka ah, porosity hooseeya, iyo korantada korantada qaarkood, waxaana loo isticmaali karaa walxo ay ka mid yihiin biraha dhalada dhalada iyo tuubooyinka qabyada ah.

Halabuurka siliconizedgraphite waa lebis, dusha sare waa la socda gudaha, iyo saamiga ka kooban ee carbide silicon iyo graphite waa hagaajin. Maaddaama ay ka sii badan tahay maadada silikoon carbide, cufnaanta maaddadu way sii badanaysaa, way sii badanaysaa xoogga cufan, adkaysiguna wuu kordhaa.

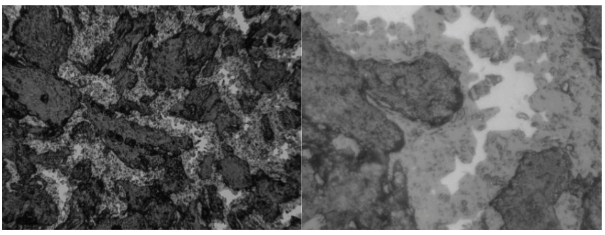

Sawirka biraha ee silikoonizedgaraafka

(Qeybta madow waa graphite, qeybta cawl waa silicon carbide, qeybta cadna waa silikoon)

| 硅化石墨主要技术指标 | |

| 类别 Shayga | 指标 Qiimaha |

| 密度 Cufnaanta | 2.4-2.9g/cm³ |

| 孔隙率 Porosity | <0.5% |

| 抗压强度Xoog cadaadis leh | > 400MPa |

| 抗折强度 Xoog dabacsanaan Xoog dabacsanaan | > 120MPa |

| 热导率 Dhaqdhaqaaqa kulaylka | 120W/mK |

| 热膨胀系数Isku xidhka balaadhinta kulaylka | 4.5×10-6 |

| 弹性模量modules laastikada | 120GPa |

| 冲击强度Awood saamayn | 1.9KJ/m² |

| 水润滑摩擦系数 Khilaaf biyo salaysan | 0.005 |

| 干摩擦系数Isku dhafka qallalan ee qallafsan | 0.05 |

| 化学稳定性 Degganaanshaha kiimikada | 各种盐,有机溶剂,强酸(HF, HCl, H₂SO4, HNO₃) Cusbo kala duwan, dareere organic, acids xooggan (HF, HCl, H₂SO4, HNO₃) |

| 长期稳定使用温度 heerkulka isticmaalka muddada-dheer deggan | 800℃(氧化气氛), 2300℃(惰性或真空气氛) 800 ℃ 2300 ℃ |

| 电阻率 Iska caabin koronto | 120×10-6Ωm |