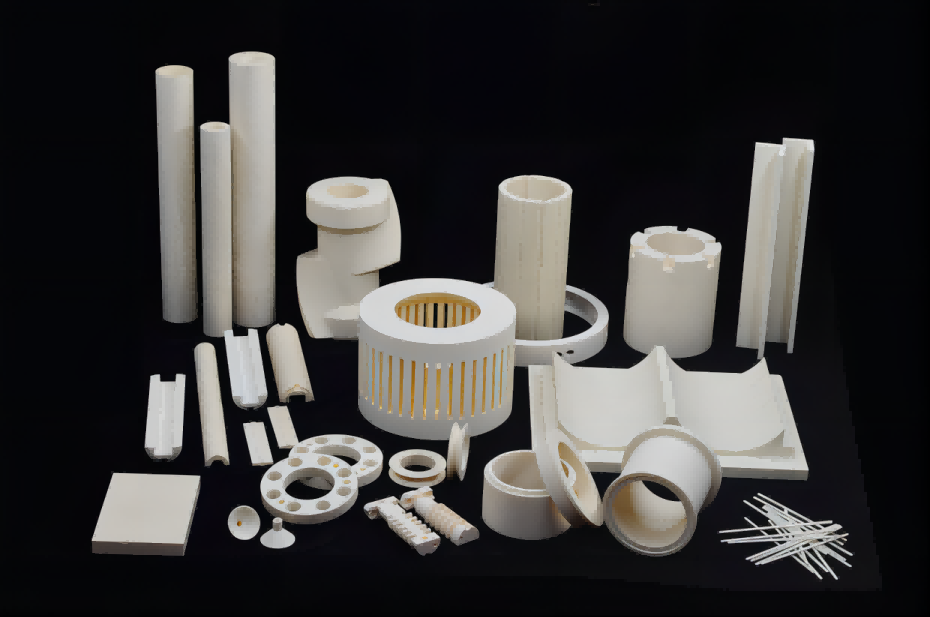

Alumina ceramics waa nooc ka mid ah alumina (Al2O3) oo ah alaabta dhoobada ugu weyn, hadda waa mid ka mid ah dhoobada gaarka ah ee caadiga ah, waxaa si ballaaran loogu isticmaali karaa warshadaha casriga ah iyo kuwa goynta, sida microelectronics, reactors nukliyeerka, aerospace, magnetic. soo saarista tamarta dareeraha ah, lafo macmal ah iyo kala goysyada macmalka ah iyo dhinacyo kale, oo ay dadku raalli ka yihiin iyo jacaylka.

Qalabka dhoobada alumina waxay leeyihiin faa'iidooyinka soo socda:

1, adkaanta ceramics alumina waa mid aad u sarreeya, caabbinta xirashada wanaagsan.

2, ceramics alumina waxay leeyihiin caabbinta daxalka kiimikaad iyo sifooyin dahab ah oo dhalaalay.

3, alaabta dhoobada alumina waxay leedahay dahaar aad u fiican, luminta soo noqnoqda sare waa mid aad u yar laakiin sifooyin heer sare ah oo wanaagsan.

4, alaabta dhoobada alumina waxay leedahay sifooyinka caabbinta kulaylka, isugeynta yar ee ballaarinta kulaylka, xoog farsamo oo weyn iyo kuleylka kuleylka wanaagsan.

5, caabbinta xirashada ceramics alumina waa wanaagsan tahay, laakiin adayggu wuxuu la mid yahay kan corundum, iyo iska caabbinta xirashada heerka adag ee Mohs 9 waxay la mid tahay tan Alloys adag.

6, ceramics alumina waxay leeyihiin sifooyin aan guban karin, miridhku, ma fududa in la dhaawaco, taas oo ah walxaha kale ee organic iyo walxaha birta ah ma u dhigmi karaan waxqabadka ugu fiican.

| Qiyaasaha Farsamada | ||

| Mashruuca | Unug | Qiimaha tirada |

| Qalab | / | Al2O3 :99.5% |

| Midabka | / | Caddaan, fool maroodi |

| Cufnaanta | g/cm3 | 3.92 |

| Xoog Jilicsan | MPa | 350 |

| Xoog isku dhejisan | MPa | 2,450 |

| Modulka dhalinyarada | GPA | 360 |

| Xoogga Saamaynta | MPa m1/2 | 4-5 |

| Weibull Coefficient | m | 10 |

| Vickers Hardness | HV 0.5 | 1,800 |

| (Iskudarka Balaadhinta kulaylka) | 1n-5k-1 | 8.2 |

| Habdhaqanka kulaylka | W/mK | 30 |

| Deganaanshaha shoogga kulaylka | △T°C | 220 |

| Heerkulka Isticmaalka ugu badan | °C | 1,600 |

| 20°C Cabbitaanka Mugga | Ωcm | >1015 |

| Xoogga Dielectric | kV/mm | 17 |

| Dielectric Constant | εr | 9.8 |