Silicon carbide (SiC) walxo crystal ah oo kali ah ayaa leh ballac ballaaran oo faaruq ah (~ Si 3 jeer), korantada kuleylka sare (~ Si 3.3 jeer ama GaAs 10 jeer), heerka guuritaanka korantada elektaroonigga sare (~ Si 2.5 jeer), koronto jaban oo sarreeya garoonka (~ Si 10 jeer ama GaAs 5 jeer) iyo astaamo kale oo muuqda.

Qalabka jiilka seddexaad ee semiconductor inta badan waxaa ka mid ah SiC, GaN, dheeman, iwm., sababtoo ah ballaca farqiga band (Tusaale ahaan) wuu ka weyn yahay ama la siman yahay 2.3 volts elektaroonik ah (eV), oo sidoo kale loo yaqaan qalabka farqiga ballaaran ee semiconductor. Marka la barbardhigo jiilka koowaad iyo labaad ee qalabka semiconductor, jiilka saddexaad ee qalabka semiconductor waxay leeyihiin faa'iidooyinka kuleylka kuleylka sare, burburka sare ee korantada, heerka guuritaanka korantada sare ee korantada iyo tamarta isku-xidhka sare, kaas oo buuxin kara shuruudaha cusub ee tiknoolajiyada casriga ah ee elektiroonigga ah ee sare. heerkulka, awoodda sare, cadaadis sare, soo noqnoqda sare iyo caabbinta shucaaca iyo xaalado kale oo adag. Waxay leedahay rajada codsiga muhiimka ah ee beeraha difaaca qaranka, duulista, hawada, sahaminta saliidda, kaydinta indhaha, iwm, iyo hoos u dhigi kartaa khasaaraha tamarta by in ka badan 50% in warshado badan oo istiraatiiji ah sida isgaarsiinta broadband, tamarta qoraxda, wax soo saarka baabuurta, nalalka semiconductor, iyo grid smart, oo yarayn kara mugga qalabka in ka badan 75%, taas oo muhiim u ah horumarka sayniska iyo tignoolajiyada aadanaha.

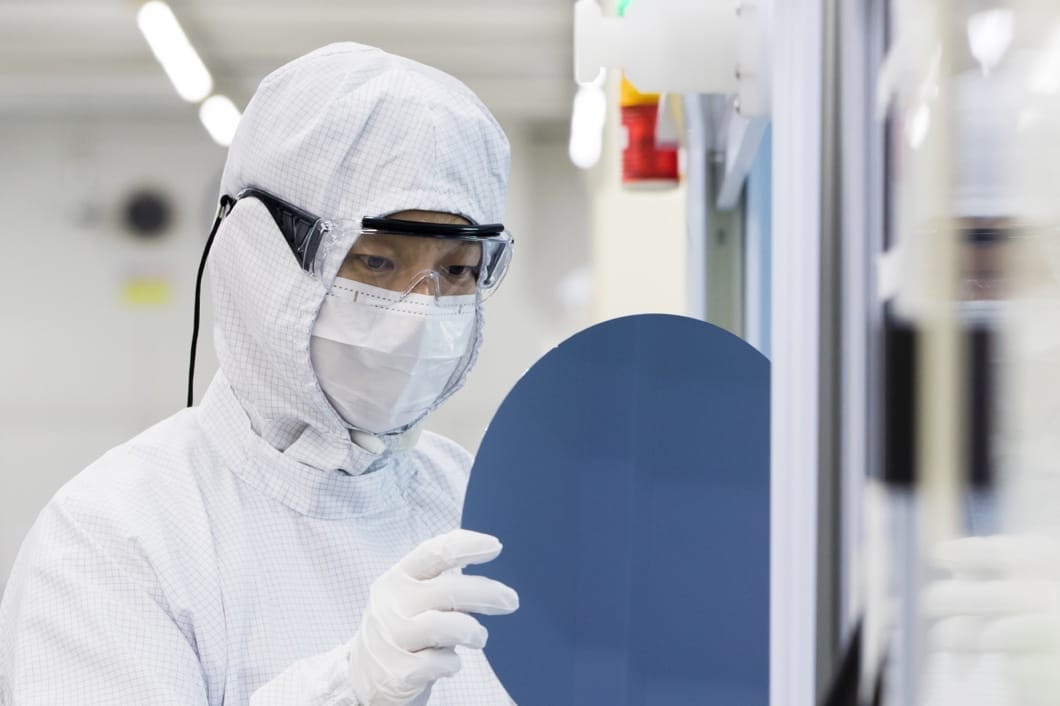

Tamarta Semicera waxay siin kartaa macaamiisha tayada tayada sare leh ee Wax-qabad (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) substrate silicon carbide; Intaa waxaa dheer, waxaan ku siin karnaa macaamiisha silikoon carbide xaashida epitaxial isku mid ah oo isku mid ah; Waxaan sidoo kale u habeyn karnaa xaashida epitaxial iyadoo loo eegayo baahiyaha gaarka ah ee macaamiisha, mana jirto wax dalab ah oo ugu yar.

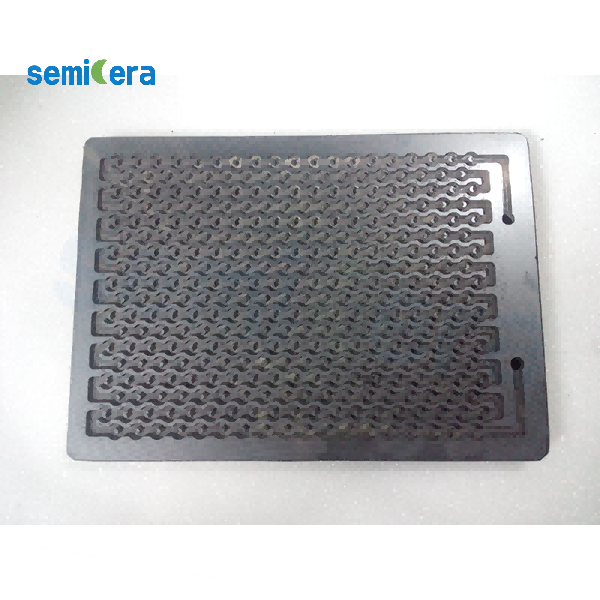

| Walxaha | Wax soo saar | Cilmi baaris | nacasnimo |

| Qiyaasta Crystal | |||

| Noocyo badan | 4H | ||

| Khaladka jihaynta dusha sare | <11-20>4±0.15° | ||

| Halbeegyada Korontada | |||

| Dopant | n-nooca Nitrogen | ||

| iska caabin | 0.015-0.025ohm · cm | ||

| Halbeegyada Makaanikada | |||

| Dhexroorka | 150.0 ± 0.2mm | ||

| Dhumucda | 350± 25 μm | ||

| Hanuuninta fidsan ee aasaasiga ah | [1-100]±5° | ||

| Dhererka siman ee aasaasiga ah | 47.5 ± 1.5mm | ||

| Dabaqa labaad | Midna | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Qaansada | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Wajiga hore (Si-wejiga) qallafsanaanta (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Qaab dhismeedka | |||

| Cufnaanta tuubbada yar | <1 ea/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Wasakhda birta | ≤5E10atom/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Tayada hore | |||

| Hore | Si | ||

| Dhammaadka dusha sare | Si-wejiga CMP | ||

| Qaybaha | ≤60ea/wafer (xajmiga≥0.3μm) | NA | |

| xoqid | ≤5ea/mm Dhererka isugeynta ≤ Dhexroorka | Dhererka isugeynta≤2* Dhexroor | NA |

| Diirka liimiga ah/gomayska/ wasakhowga/ dildilaaca/ wasakhowga | Midna | NA | |

| Chips-ka-geeska/indents/jabka/taargada hex | Midna | ||

| Aagagga nooca badan | Midna | Aagga isugeynta≤20% | Aagga isugeynta≤30% |

| Calaamadaynta laysarka hore | Midna | ||

| Tayada dambe | |||

| Dhammaadka dhabarka | C-wajiga CMP | ||

| xoqid | ≤5ea/mm, Dhererka isugeynta≤2* Dhexroor | NA | |

| Cilladaha dhabarka (dhab-jeexyada geesaha) | Midna | ||

| Dhabar xumada | Ra≤0.2nm (5μm*5μm) | ||

| Calaamadaynta laser-ka dambe | 1 mm (laga bilaabo cidhifka sare) | ||

| Cidhif | |||

| Cidhif | Chamfer | ||

| Baakadaha | |||

| Baakadaha | Epi-diyaar ah oo leh baakad vacuum ah Baakadaha cajaladaha wafer-ka badan | ||

| * Xusuusin: "NA" macnaheedu waa codsi la'aan Waxyaabaha aan la sheegin waxay tixraaci karaan SEMI-STD. | |||