Semicerasi sharaf leh ayaa u soo bandhigaysa4" Gallium Oxide Substrates, walxo cusub oo loo farsameeyay si loo daboolo baahida sii kordheysa ee aaladaha semiconductor ee waxqabadka sare leh. Gallium oxide (Ga2O3Substrates-yadu waxay bixiyaan faashad aad u ballaadhan, taas oo ka dhigaysa inay ku habboon yihiin korantada soo socota ee elektiroonigga ah, UV optoelectronics, iyo aaladaha soo noqnoqda.

Astaamaha Muhiimka ah:

• Bandgap aadka u ballaadhan: The4" Gallium Oxide SubstratesKu faano bandgap ah qiyaastii 4.8 eV, taas oo u oggolaanaysa koronto aan caadi ahayn iyo dulqaadka heerkulka, oo si weyn uga sarreeya agabka semiconductor-ka caadiga ah sida silicon.

•Korontada Burburka SareSubstrate-yadani waxay awood u siinayaan aaladaha inay ku shaqeeyaan koronto iyo awood sare, taasoo ka dhigaysa inay ku fiican yihiin codsiyada korantada sare ee korantada elektiroonigga ah.

•Deganaanshaha kulaylka SareQaybaha Gallium Oxide waxay bixiyaan hab-kuleyl heer sare ah, hubinta waxqabadka xasilloon ee xaaladaha aadka u daran, oo ku habboon isticmaalka jawiga baahida.

•Tayada Qalabka Sare: Cufnaanta cilladaha hooseeya iyo tayada sare ee crystal, substrate-yadani waxay xaqiijinayaan waxqabad la isku halleyn karo oo joogto ah, kor u qaadida waxtarka iyo adkeysiga qalabkaaga.

•Codsiga Kala Duwan: Ku habboon codsiyo kala duwan oo kala duwan, oo ay ku jiraan transistor-ka korantada, Schottky diodes, iyo UV-C LED qalabyada, oo awood u siinaya hal-abuurnimo labadaba awoodda iyo goobaha optoelectronic.

Ku sahamin mustaqbalka tignoolajiyada semiconductor-ka Semicera's4" Gallium Oxide Substrates. Substrate-yadayada waxaa loogu talagalay inay taageeraan codsiyada ugu horumarsan, iyagoo siinaya isku halaynta iyo hufnaanta looga baahan yahay aaladaha goynta maanta. Ku kalsoonow Semicera tayada iyo hal-abuurka qalabkaaga semiconductor.

| Walxaha | Wax soo saar | Cilmi baaris | nacasnimo |

| Qiyaasta Crystal | |||

| Noocyo badan | 4H | ||

| Khaladka jihaynta dusha sare | <11-20>4±0.15° | ||

| Halbeegyada Korontada | |||

| Dopant | n-nooca Nitrogen | ||

| iska caabin | 0.015-0.025ohm · cm | ||

| Halbeegyada Makaanikada | |||

| Dhexroorka | 150.0 ± 0.2mm | ||

| Dhumucda | 350± 25 μm | ||

| Hanuuninta fidsan ee aasaasiga ah | [1-100]±5° | ||

| Dhererka siman ee aasaasiga ah | 47.5 ± 1.5mm | ||

| Dabaqa labaad | Midna | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Qaansada | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Wajiga hore (Si-wejiga) qallafsanaanta (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Qaab dhismeedka | |||

| Cufnaanta tuubbada yar | <1 ea/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Wasakhda birta | ≤5E10atom/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Tayada hore | |||

| Hore | Si | ||

| Dhammaadka dusha sare | Si-wejiga CMP | ||

| Qaybaha | ≤60ea/wafer (xajmiga≥0.3μm) | NA | |

| xoqid | ≤5ea/mm Dhererka isugeynta ≤ Dhexroorka | Dhererka isugeynta≤2* Dhexroor | NA |

| Diirka liimiga ah/gomayska/ wasakhowga/ dildilaaca/ wasakhowga | Midna | NA | |

| Chips-ka-geeska/indents/jabka/taargada hex | Midna | ||

| Aagagga nooca badan | Midna | Aagga isugeynta≤20% | Aagga isugeynta≤30% |

| Calaamadaynta laysarka hore | Midna | ||

| Tayada dambe | |||

| Dhammaadka dhabarka | C-wajiga CMP | ||

| xoqid | ≤5ea/mm, Dhererka isugeynta≤2* Dhexroor | NA | |

| Cilladaha dhabarka (dhab-jeexyada geesaha) | Midna | ||

| Dhabar xumada | Ra≤0.2nm (5μm*5μm) | ||

| Calaamadaynta laser-ka dambe | 1 mm (laga bilaabo cidhifka sare) | ||

| Cidhif | |||

| Cidhif | Chamfer | ||

| Baakadaha | |||

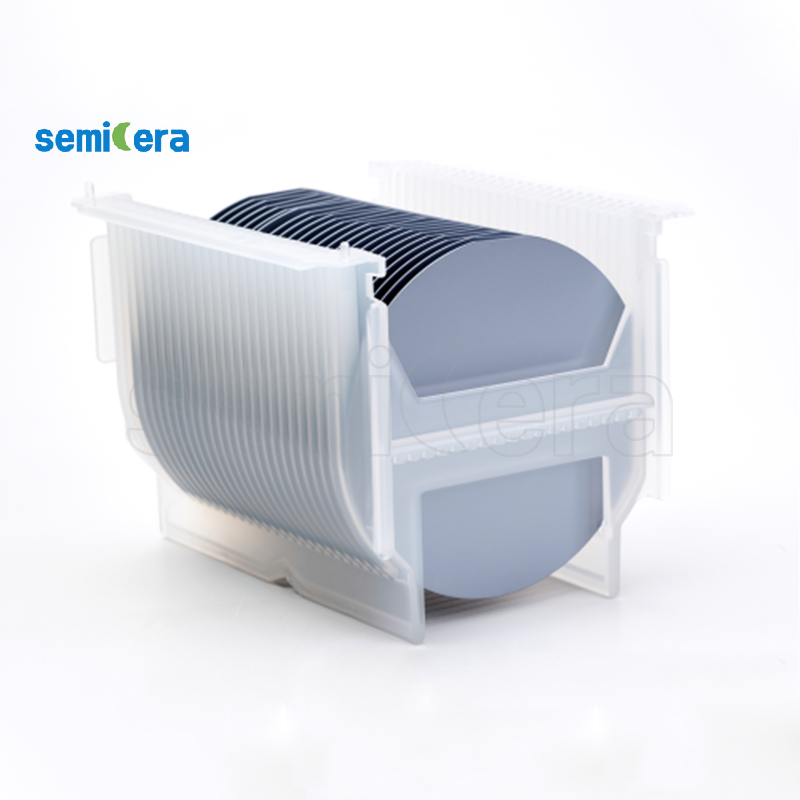

| Baakadaha | Epi-diyaar ah oo leh baakad vacuum ah Baakadaha cajaladaha wafer-ka badan | ||

| * Xusuusin: "NA" macnaheedu waa codsi la'aan Waxyaabaha aan la sheegin waxay tixraaci karaan SEMI-STD. | |||