Semicerawuu ku faraxsan yahay inuu bixiyo2" Gallium Oxide Substrates, Qalab goynta ah oo loogu talagalay in lagu wanaajiyo waxqabadka qalabka semiconductor sare. Substrate-yadan, oo laga sameeyay Gallium Oxide (Ga2O3), waxay muujisaa xadhig aad u ballaadhan, taas oo ka dhigaysa doorashada ugu habboon ee awoodda sare, soo noqnoqoshada sare, iyo codsiyada UV optoelectronic.

Astaamaha Muhiimka ah:

• Bandgap aadka u ballaadhan: The2" Gallium Oxide Substrateswaxay bixiyaan gaab heersare ah oo qiyaastii ah 4.8 eV, taas oo u oggolaanaysa koronto sare iyo hawlgal heerkul ah, oo aad uga badan awoodaha agabka semiconductor-ka caadiga ah sida silicon.

•Korantada Burburka Gaarka ahSubstrates-yadani waxay awood u siinayaan aaladaha inay xamili karaan koronto aad u sarreeya, taasoo ka dhigaysa inay ku fiican yihiin qalabka korantada, gaar ahaan codsiyada korantada sare.

•Habdhaqan kuleyl heer sare ah: Iyada oo xasilloonida kulaylka sare, substrate-yadani waxay ilaalinayaan waxqabadka joogtada ah xitaa jawi kuleyl ah, oo ku habboon codsiyada heerkulka sare iyo heerkulka sare.

•Qalab tayo sare leh: The2" Gallium Oxide SubstratesBixi cufnaanta cilladaha hooseeya iyo tayada crystalline sare, hubinta waxqabadka la isku halayn karo oo hufan ee aaladahaaga semiconductor.

•Codsiyada kala duwan: Substrates-yadani waxay ku habboon yihiin codsiyo kala duwan, oo ay ku jiraan transistor-ka korantada, Schottky diodes, iyo UV-C LED qalabyada, oo bixiya aasaas adag oo labadaba awoodda iyo hal-abuurka optoelectronic.

Ku fur awoodda buuxda ee aaladahaaga semiconductor-ka Semicera's2" Gallium Oxide Substrates. Substratesyadayada waxaa loo qaabeeyey si ay u daboolaan baahida baahida codsiyada maanta, hubinta waxqabadka sare, isku halaynta, iyo hufnaanta. U dooro Semicera agabka semiconductor-ka ugu casrisan ee dhaqaajiya hal-abuurka.

| Walxaha | Wax soo saar | Cilmi baaris | nacasnimo |

| Qiyaasta Crystal | |||

| Noocyo badan | 4H | ||

| Khaladka jihaynta dusha sare | <11-20>4±0.15° | ||

| Halbeegyada Korontada | |||

| Dopant | n-nooca Nitrogen | ||

| iska caabin | 0.015-0.025ohm · cm | ||

| Halbeegyada Makaanikada | |||

| Dhexroorka | 150.0 ± 0.2mm | ||

| Dhumucda | 350± 25 μm | ||

| Hanuuninta fidsan ee aasaasiga ah | [1-100]±5° | ||

| Dhererka siman ee aasaasiga ah | 47.5 ± 1.5mm | ||

| Dabaqa labaad | Midna | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Qaansada | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Wajiga hore (Si-wejiga) qallafsanaanta (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Qaab dhismeedka | |||

| Cufnaanta tuubbada yar | <1 ea/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Wasakhda birta | ≤5E10atom/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Tayada hore | |||

| Hore | Si | ||

| Dhammaadka dusha sare | Si-wejiga CMP | ||

| Qaybaha | ≤60ea/wafer (xajmiga≥0.3μm) | NA | |

| xoqid | ≤5ea/mm Dhererka isugeynta ≤ Dhexroorka | Dhererka isugeynta≤2* Dhexroor | NA |

| Diirka liimiga ah/gomayska/ wasakhowga/ dildilaaca/ wasakhowga | Midna | NA | |

| Chips-ka-geeska/indents/jabka/taargada hex | Midna | ||

| Aagagga nooca badan | Midna | Aagga isugeynta≤20% | Aagga isugeynta≤30% |

| Calaamadaynta laysarka hore | Midna | ||

| Tayada dambe | |||

| Dhammaadka dhabarka | C-wajiga CMP | ||

| xoqid | ≤5ea/mm, Dhererka isugeynta≤2* Dhexroor | NA | |

| Cilladaha dhabarka (dhab-jeexyada geesaha) | Midna | ||

| Dhabar xumada | Ra≤0.2nm (5μm*5μm) | ||

| Calaamadaynta laser-ka dambe | 1 mm (laga bilaabo cidhifka sare) | ||

| Cidhif | |||

| Cidhif | Chamfer | ||

| Baakadaha | |||

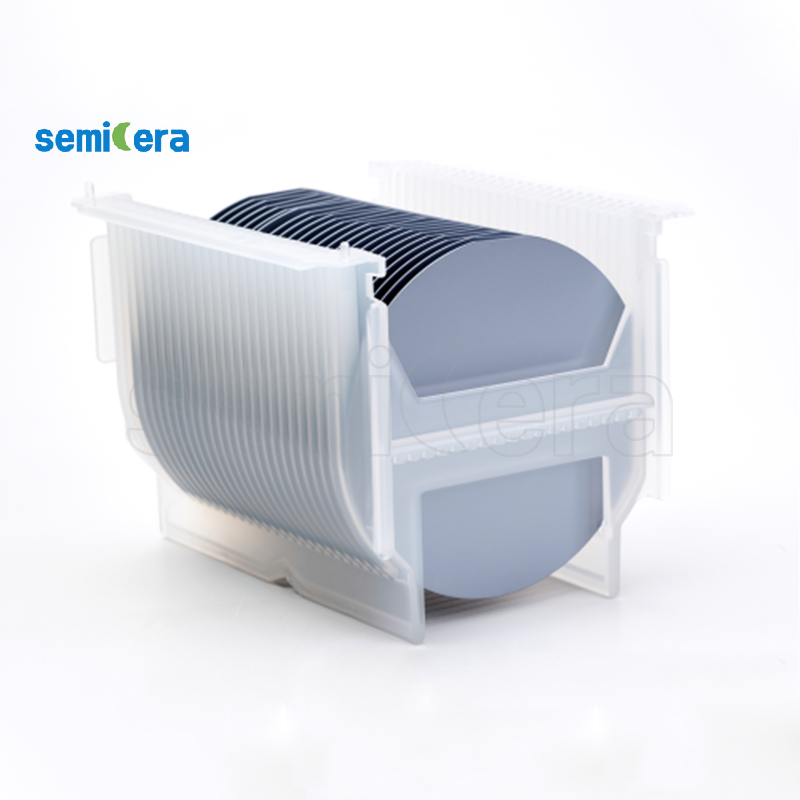

| Baakadaha | Epi-diyaar ah oo leh baakad vacuum ah Baakadaha cajaladaha wafer-ka badan | ||

| * Xusuusin: "NA" macnaheedu waa codsi la'aan Waxyaabaha aan la sheegin waxay tixraaci karaan SEMI-STD. | |||